Governor

El gobernador de la unidad de spirit (llamado gobernador externo) se puede utilizar con todas las conexiones de receptor digital de línea única. Esto significa que para pwm y ppm no se puede usar. Para que funcione, tendrá que obtener un sensor de rpm que puede suministrar a la unidad con los datos actuales rpm.

This mean that for PWM and PPM it cannot be used. To make it work, you will need to get a RPM Sensor which can supply the unit with current RPM data.

Contents

- 1 Wiring

- 2 Lista de sensores probados

- 3 Activation

- 4 Spirit Settings

- 5 Throttle Channel verification

- 6 Electric motors - ESC Setup

- 7 Combustion motors - Throttle Servo Setup

- 8 Radio Setup - Throttle Curve

- 9 Governor Setup Procedure

- 10 First start

- 11 Rescate de autorrotación

- 12 Acelerador para la rotación automática (opciónal)

- 13 solución de problemas

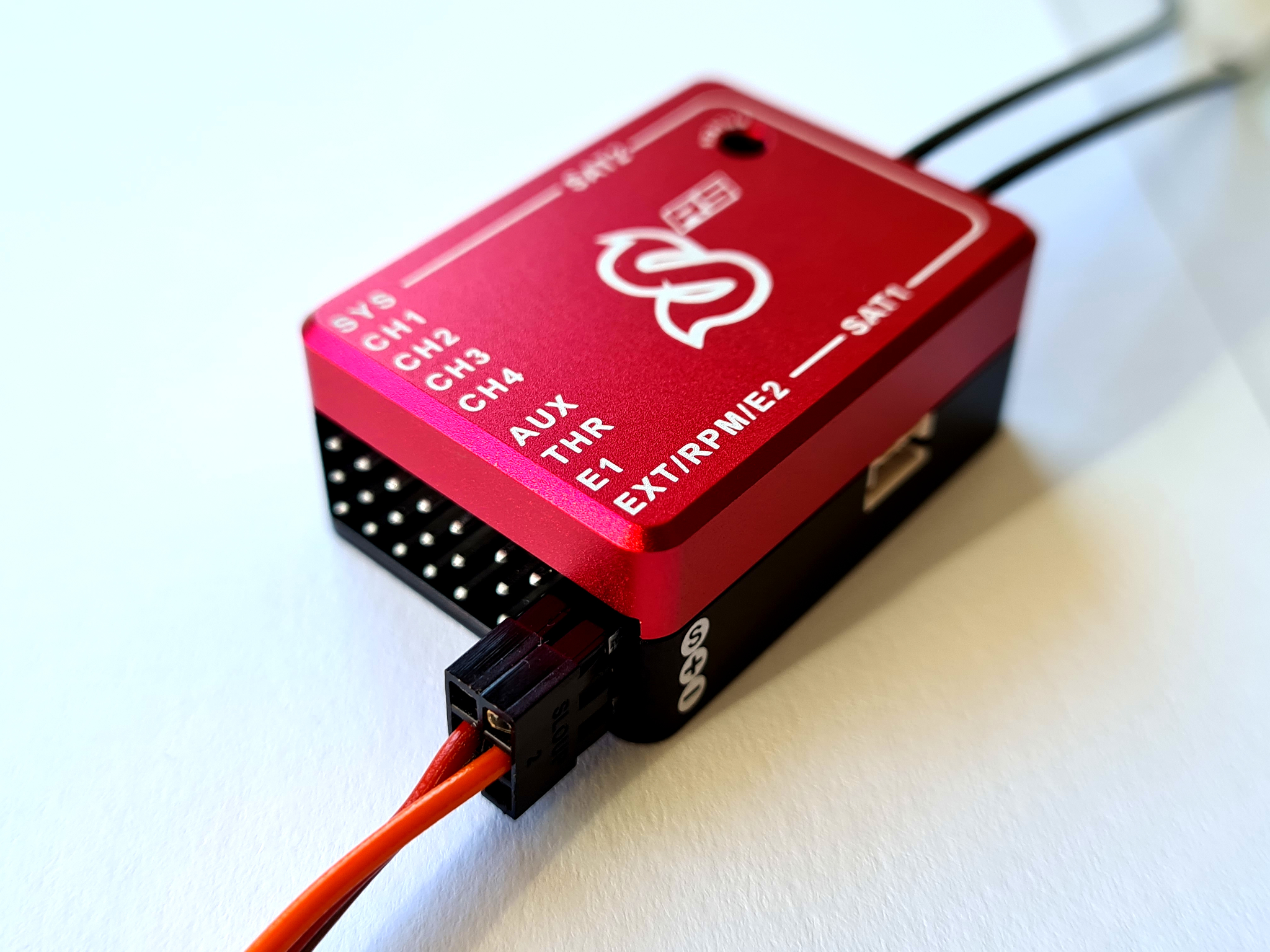

1 Wiring

1.1 Throttle

Para el uso de este regulador es necesario conectar el acelerador (esc o el servo del acelerador) en el puerto aux(aux1).

1.2 RPM signal

Para que el gobernador funcione bien es muy importante elegir un sensor de rpm apropiado. Los siguientes son conocidos para trabajar bien.

Cable that carry RPM signal must be always connected when Governor is used.

Connect RPM signal cable to the pin of the unit:

- μSpirit - P pin - pin in the middle of P/E/A port

- Spirit - PIT pin - pin in the middle of ELE/PIT/AIL port

- Spirit Pro and Spirit 2 - PIT pin - pin in the middle of ELE/PIT/AIL port

- Spirit RS - RPM pin - pin in the middle of EXT/RPM/E2 port

Sensor can be powered from any available Satellite port (SAT) or directly from a BEC. Satellite port is giving 3.3V, while BEC is operating usually at 5 - 8V.

1.3 Wiring example

Red (+3.3V), Brown (GND).

2 Lista de sensores probados

The following are known to work well.

- motor electrico

- HobbyWing Platinum ESC v3/v4 RPM output

- YGE ESC RPM output

- CC Phoenix Edge RPM output

- Scorpion Commander V RPM output

- HobbyWing RPM Sensor

- Hyperion RPM Sensor

- Orange RPM Sensor

- Nitro and Gasser Motor

3 Activation

To activate Governor feature in the Spirit unit, you will need to assign Throttle function in the General tab/Channels. Then you will be able to enter Governor Settings in the General tab.

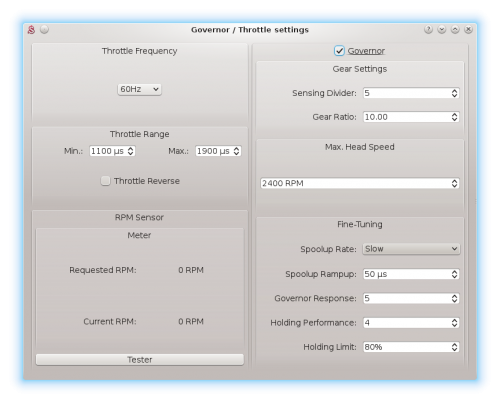

4 Spirit Settings

First from all basic settings are necessary so the governor can control the head speed correctly. Please review all the parameters prior any configuration.

Throttle frequency

To achieve the fastest governor reaction it is necessary to set the highest possible frequency. For ESC it could be only 60Hz, but mostly all can work even with 200Hz. If you are unsure, please contact manufacturer of the ESC. For combustion helicopters it is max. operating frequency of the throttle servo.

Throttle Range

This parameter can affect output from the unit so you can fine-tune ranges precisely. For electric helicopters this parameter is optional. But in case that your ESC does not allow to calibrate throttle range correctly, you can do so here. For Nitro and Gasser helicopters you have to configure it always so the Throttle servo range matches range for the motor.

Throttle Range - Min.

Value of the lowest throttle signal. Default value: 1100 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

Parameter is optional - you do not have to change it if your ESC support the throttle calibration (e.g. by sticks).

You should set the lowest position when the motor is not spinning up anymore – is halted. While configuring this, the motor can start so you have to be very carefull.

For combustion helicopters it is important to set the value at the point when Engine carburetor is fully closed, but right before point it starts to be open.

Throttle Range – Max.

Value of the highest throttle signal. Default value: 1900 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

Parameter is optional - you do not have to change it if your ESC support the throttle calibration (e.g. by sticks).

The value should be configured to match with 100% throttle output programmed in your ESC or full throttle of the motor. If this parameter is not high enough you will be unable to tune Governor because there will be not enough room to compensate high loads. If configured too high then you can observe that after high load head speed will not drop immediately but can be there even for few seconds.

For combustion helicopters it is important to set the value at the point when Engine carburetor is fully open, but right before point the valve is closing. The best is to check the carburetor valve optically to see in which position it is. Adding more than required will cause overspeeding issue.

Throttle Reverse

Especially for Nitro and Gasser motors you can set correct compensation direction for the servo here.

Gear Settings - Sensing Divider

Electric motor: Motor poles / 2. For a 10 pole motor set divider to number 5. Mostly configured to 3 – 5.

Nitro/Gasser motor: Number of all active magnets. Mostly it is 1 – 2.

Gear Settings - Gear Ratio

Gear Ratio of the helicopter between the main wheel and pinion of the motor. For example: 120T main gear / 12T pinion = 10.

Max. Head Speed

Configure max. head speed that should be achieved with 100% throttle curve. For example: If you know that you won't exceed 2500 RPM then you can set the value to 2500. With 80% throttle curve your head speed will be 2000 RPM (2500 * 0.80 = 2000).

Fine-Tuning – Spoolup rate

Configure speed of the motor spoolup. For initial tests we recommend Slow spoolup rate.

Fine-Tuning – Spoolup Rampup

Value that will be added at the beginning of motor spoolup – when Hold is turned off. If the spoolup is not smooth, i.e. motor will start with a kick, the value is too high. If the spoolup has a delay, the value is too low. Default value of 50 μs should work fine in the most cases.

Fine-Tuning - Governor Response

This parameter is the most important one to achieve fast and proper response of the governor. It determine how fast the governor should react to a short-term load. Thus optimal settings are required. If configure too low or too high, rudder will not hold properly and can oscillate. Governor can greatly affect rudder performance so you can achieve better holding behavior. Too high value will result in overspeeding during e.g. pitch pump.

Fine-Tuning - Holding Performance

Determine how well the head speed is maintained during a long-term load. If value is too low then during e.g. tic-toc maneuver head speed can drop gradually. In case it is too high then after the tic-toc head speed can be higher than necessary and can even return to requested RPM with noticeable delay. It is better to start governor tuning process with low value.

Fine-Tuning - Holding Limit

Prevents from prolonged overspeeding after demanding maneuvers. If head speed is higher than requested after demanding maneuver then by decreasing percentage value it is possible to shorten or eliminate this odd behavior. If Limit value is too low then Holding Performance will not affect Governor performance. It is recommended to use 80% for the most helicopters. Usually combustion helicopters might need to decrease the Limit. Changing the Limit as the last parameter of the Governor is recommended - once a proper Governor Response and Holding Performance values are configured.

5 Throttle Channel verification

Set the Throttle Range in your transmitter so that 0% and 100% throttle position matches with value of the Throttle bar in the Diagnostic tab. This can be done by Subtrim function in your transmitter and/or Travel Adjust function. When 0% or 100% throttle curve value in your radio is configured and Diagnostic tab in the Spirit Settings will show the same, then Throttle channel in your radio is configured well.

6 Electric motors - ESC Setup

6.1 ESC Throttle Calibration

Before you can use Spirit Governor, Throttle Range in the Spirit and ESC must match with each other. For this purpose Throttle Calibration is performed. For the most ESCs you can find out what factory Throttle signal range is. If you know these two values (usually near 1100 - 1900) you do not have to perform Throttle Calibration. Each ESC manufacturer can have a slightly different values. If you will set these values in the Spirit unit, then the throttle range should match perfectly. If you performed Throttle Calibration in the past then the following procedure is necessary.

- Turn off Spirit Governor in order to perform Throttle Calibration.

- Set linear Throttle curve in your radio transmitter so that 0% and 100% throttle position matches with value of the Throttle bar in the Diagnostics tab. If it is not matching, use Subtrim function in your transmitter and/or Travel Adjustment function.

- Re-calibrate Throttle Range according the instructions of your ESC. In the most cases it can be configured by powering the model with throttle stick with 100% throttle and then by moving the stick down to 0%.

- Now you can enable Spirit Governor again.

6.2 ESC setup

To obtain good performance, configure fast spoolup mode in the ESC so the governor spoolup procedure will not interfere with ESC.

Some ESC offer specific settings for External Governor. Please set mode recommended by ESC manufacturer.

7 Combustion motors - Throttle Servo Setup

Please set Throttle Range and Throttle Reverse parameters in the Spirit Settings software to match carburator range precisely.

8 Radio Setup - Throttle Curve

Flat Throttle Curve above 50% is necessary in order to use Governor feature. Under 50% Governor is immediately disarmed and instead motor will be driven directly by throttle curve. As soon as it will exceed 50% spoolup procedure is engaged until Requested RPM is reached. Only when Flight log will show Governor was Engaged then Governor is maintaining Head-Speed. If this message is not present it mean that Governor is still in the spoolup procedure.

In order to achieve different Head Speeds on demand you can set different flat curves (for example for each flight mode).

Governor can be deactivated in flight by switching to a Bank where Governor is disabled in the Spirit Settings. It can be also re-activated by switching back to a Bank with enabled Governor.

For Electric motors you can go from Throttle Hold to a flat Throttle Curve above 50%. This will always trigger smooth spoolup.

For Combustion motors we recommend to go from Idle RPM (Throttle Curve around 10%) directly to 50% flat curve and above. This will trigger smooth spoolup as well.

9 Governor Setup Procedure

Firstly you have to finish basic setup. Please set Max. Head Speed, Sensing Divider and Gear Ratio parameters now. Throttle curve in the transmitter must be always FLAT when using Spirit Governor. We recommend to set the Throttle curve for example to flat 70%, 80% or 90%.

After disarming Throttle Hold you should immediately see Requested RPM in the software – this is desired head speed that should be maintained. Current RPM is head speed that is currently on the rotor head. If Current RPM is not calculated properly, then there is a problem with Gear Settings. In case that you can see zero or random Current RPM value then there is a problem with RPM Sensor and must be fixed.

9.1 Performance tuning procedure

We recommend to set the following values for the beginning:

- Governor Response: 5

- Holding Performance: 1

- You should start with increasing the Governor Response. You can do so until RPM is constant enough while doing aggressive collective pitch changes during hovering. When you will notice an overspeeding (RPM is higher than initially was) then the value is too high. In case that the value is too low or too high then the rudder performance can be affected negatively as well.

- When the Governor Response is well tuned, you can continue with increasing the Holding Performance parameter. In case that the value is too low, you will notice poor holding performance during demanding maneuvers with longer duration such as loop or tic-toc. If the value is too high, you can observe that the head speed is unstable even during stationary hovering.

Governor Response: 6 and Holding Performance: 5 may work fine for wide range of the helicopters.

10 First start

Once model is prepared at the flying field, please disarm Throttle Hold. Motor should start immediately, slowly and preferably without any kick. If not, please tune Spoolup Rate, Spoolup Rampup or a Start Power parameter in the ESC settings.

Wait until model will achieve Requested RPM and then lift off. If some tuning is needed, always land and stop the motor.

11 Rescate de autorrotación

Para los pilotos que están realizando autorotaciones la función de rescate puede ser útil. Esta característica permite girar el motor a las rpm de vuelo rápidamente cuando sea necesario. Puede cambiar la tasa de rescate de autorotación en la configuración avanzada / experta .

Con el fin de hacer que funcione sólo tiene que configurar su transmisor.

- Al hacer la autorrotación no enganchar la sujeción del acelerador.

- Utilice un interruptor asignado en su lugar, que establecerá la curva del acelerador en algún punto entre 12 - 50.

Si la curva del acelerador cae por debajo de 12 el carrete hacia arriba será normal.

12 Acelerador para la rotación automática (opciónal)

En caso de que quiera utilizar sólo el acelerador para la autorrotación, realice los siguientes pasos:

- Ajuste la curva del acelerador para mantenerla en 12. (esto hará girar el motor)

- Disminuya el rango general / regulador / acelerador - min. Hasta que el motor se detenga completamente.

- Aumente el Spoolup Rampup hasta que obtendrá bobina inmediata hasta cuando el asimiento está desarmado.

13 solución de problemas

- Un retraso entre el bloqueo del acelerador de desarme y la rotación del motor - el motor comenzará a girar después de un corto período de tiempo.

- Asegúrese de que su rango de aceleración estaba configurado correctamente. ¿Calibraste el rango del acelerador con el espíritu conectado?

- Le recomendamos que coloque el esc en los ajustes de fábrica. En la mayoría de los casos el rango predeterminado coincide con el rango preconfigurado en la unidad (1100μs - 1900μs).

- En caso de que el rango esté configurado correctamente, pero todavía hay un retraso notable, por favor, aumente el parámetro spoolup rampup hasta que el motor empiece a girar inmediatamente después de desactivar el interruptor de retención.

- El motor arrancará después de desactivar el interruptor de retención causando la rotación no deseada del modelo.

- Disminuya el parámetro spoolup rampup hasta que la patada desaparezca. Si observa un retraso antes de la cola, el valor es demasiado bajo ahora y debe utilizarse otra solución. En este caso el problema no puede ser resuelto por ningún ajuste de la unidad de spirit.

- Compruebe si el esc soporta un parámetro de potencia spoolup. Si está soportado, intente disminuir el poder y observe si le ayudará. En algunos casos una sincronización diferente o frecuencia pwm puede ayudar, pero siempre asegúrese de que los ajustes son válidos para su motor.

- Después de maniobras exigentes la velocidad de la cabeza se mantiene a mayores rpm durante un período prolongado.

- Verifique que el rango del acelerador de su esc o servo del acelerador esté configurado correctamente. Por lo general el problema es causado por el límite excedido para el acelerador completo definido por el valor margen de aceleración - valor máximo . Por ejemplo, si el límite superior en el esc se programa a 1800μs pero la unidad ha configurado 1900μs, entonces la unidad será 100μs sobre el límite real. Por lo tanto, durante una carga alta podría tomar unos segundos hasta que el valor caerá por debajo de 1800μs en este caso.

- La solución correcta es reconfigurar el rango del acelerador en la esc o en la unidad.

- Hay a menudo "rpm sensor de datos son demasiado ruidoso" evento en el registro de vuelo.

- Asegúrese de que la conexión de la salida del sensor de rpm es buena. Si el sensor de rpm está separado del esc, por favor conecte su fuente de alimentación (especialmente el cable de conexión a tierra) tan cerca como sea posible al cable de señal de rpm en la unidad. El uso de un anillo de ferrita para la fuente de alimentación podría reducir el ruido también. Verifique los requisitos de voltaje de funcionamiento del sensor. Algunos sensores requieren 3.5v o más para que no puedan ser alimentados desde el puerto spektrum de la unidad. En algunos casos es causada por un valor de respuesta del gobernador demasiado alto, porque el motor comenzará a fluctuar.

- El regulador no está cambiando entre las diferentes curvas del acelerador.

- Su rango de aceleración en el esc está calibrado incorrectamente - el rango que la unidad está programada para no coincide con el rango del esc. La calibración correcta del rango resolverá el problema.

- RPM signal was lost.

- If Governor will loose the signal, it will detect the event within 2 seconds. Governor will still work, but with worsened performance - similarly as with a V-curve. This event can happen, if the signal cable connection will fail. For this reason we highly recommend to use a hot glue or other way for securing the connections.

- Throttle calibration of the ESC is possible only if the Governor is disabled in the unit.

- For throttle curve under approx. 50% governor is inactive – throttle is controlled directly.

- You should see “Governor was Engaged” event in the log after spoolup with enabled governor.

- Governor Bailout function can be activated whenever the throttle signal is higher than 1250 μs which is approx. 12% throttle curve. If the signal is lower then smooth spoolup sequence is activated.

- In case that the Current RPM value is 8000 RPM measurement is out of range. It may be needed to change count of the active magnets.

- If governor does not react correctly during Throttle Curve changes or even during spoolup, it is most probably result of an excess noise in the RPM sensor or connection. You may consider to use a proper shielding. Increasing value of the RPM Sensor filter in the Expert settings can solve the problem.