Governor

The governor from the Spirit unit (so called External governor) can be used with all single line digital receiver connections. This mean that for PWM and PPM it cannot be used. To make it work, you will need to get a RPM Sensor which can supply the unit with current RPM data.

Contents

1 Wiring

1.1 Throttle

For usage of this governor it is necessary to connect the throttle (ESC or the Throttle servo) to the following port:

- Spirit and μSpirit - AUX port

- Spirit Pro and Spirit 2 - AUX1 port

- Spirit RS - THR port

1.2 RPM signal

To make the governor work well it is very important to choose an appropriate RPM sensor. RPM sensor can be external or built-in in the ESC.

Cable that carry RPM signal must be always connected when Governor is used.

Connect RPM signal cable to the pin of the unit:

- μSpirit - P pin - pin in the middle of P/E/A port

- Spirit - PIT pin - pin in the middle of ELE/PIT/AIL port

- Spirit Pro and Spirit 2 - PIT pin - pin in the middle of ELE/PIT/AIL port

- Spirit RS - RPM pin - pin in the middle of EXT/RPM/E2 port

Sensor can be powered from any available side Satellite port (SAT) or directly from a BEC. Side port is giving of 3.3V, while BEC is operating usually at 5 - 8V.

2 List of tested sensors

The following are known to work well.

- Electric Motors

- HobbyWing Platinum ESC v3/v4 RPM output

- YGE ESC RPM output

- CC Phoenix Edge RPM output

- Scorpion Commander V RPM output

- HobbyWing RPM Sensor

- Hyperion RPM Sensor

- Orange RPM Sensor

- Nitro and Gasser Motors

3 Wiring example

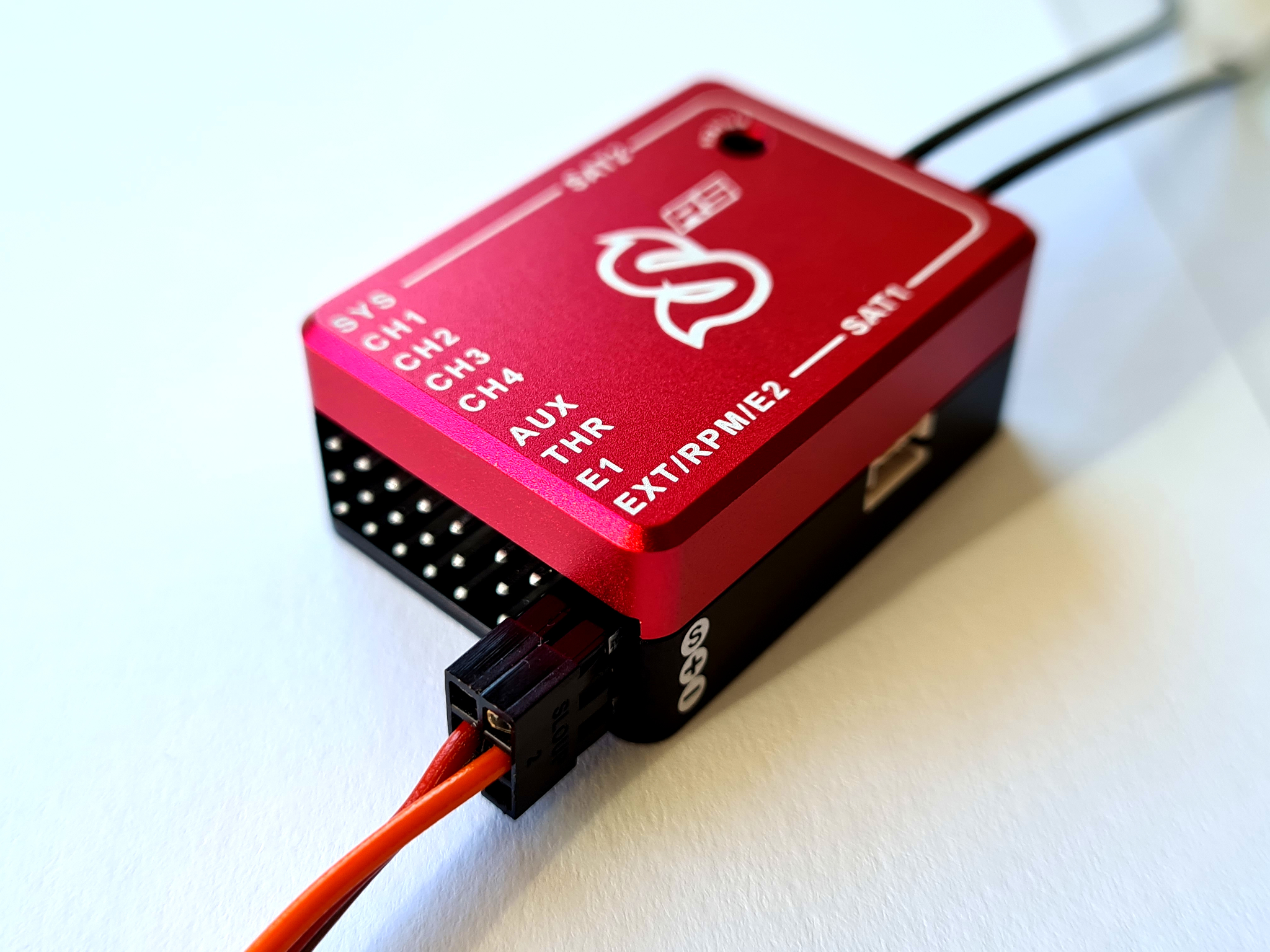

Red (+3.3V), Brown (GND).

4 Setup

4.1 Electric

- Set throttle range in your transmitter so that 0% and 100% throttle position matches with value of the throttle bar in the diagnostics tab. This can be done by Subtrim function in your transmitter and/or Travel Adjustment function.

- Re-calibrate throttle range according to instructions of your ESC. In the most cases it can be configured by powering the model with throttle stick with 100% throttle and then by moving the stick down to 0%.

- If possible, configure fast spoolup mode in the ESC so the governor will be unaffected.

4.2 Nitro / Gasser

- Set the throttle range in your transmitter so that 0% and 100% throttle position matches with value of the throttle bar in the diagnostic tab. This can be done by Subtrim function in your transmitter and/or Travel Adjust function.

5 Activation

To activate Governor feature in the unit, you will need to assign Throttle function in the General tab/Channels. Then you will be able to enter Governor Settings in the General tab.

6 Spirit Settings

First from all basic settings are necessary so the governor can control the head speed correctly.

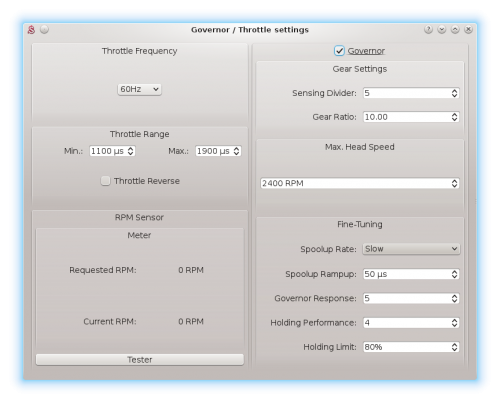

Throttle frequency

To achieve the fastest governor reaction it is necessary to set the highest possible frequency. For ESC it could be only 60Hz, but mostly all can work even with 200Hz. If you are unsure, please contact manufacturer of the ESC. For combustion helicopters it is max. operating frequency of the throttle servo.

Throttle Range

This parameter can affect output from the unit so you can fine-tune ranges precisely. For electric helicopters this parameter is optional. But in case that your ESC does not allow to calibrate throttle range correctly, you can do so here. For Nitro and Gasser helicopters you have to configure it always so the Throttle servo range matches range for the motor.

Throttle Range - Min.

Value of the lowest throttle signal. Default value: 1100 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

Parameter is optional - you do not have to change it if your ESC support the throttle calibration (e.g. by sticks).

You should set the lowest position when the motor is not spinning up anymore – is halted. While configuring this, the motor can start so you have to be very carefull.

For combustion helicopters it is important to set the value at the point when Engine carburetor is fully closed, but right before point it starts to be open.

Throttle Range – Max.

Value of the highest throttle signal. Default value: 1900 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

Parameter is optional - you do not have to change it if your ESC support the throttle calibration (e.g. by sticks).

The value should be configured to match with 100% throttle output programmed in your ESC or full throttle of the motor. If this parameter is not high enough you will be unable to tune Governor because there will be not enough room to compensate high loads. If configured too high then you can observe that after high load head speed will not drop immediately but can be there even for few seconds.

For combustion helicopters it is important to set the value at the point when Engine carburetor is fully open, but right before point the valve is closing. The best is to check the carburetor valve optically to see in which position it is. Adding more than required will cause overspeeding issue.

Throttle Reverse

Especially for Nitro and Gasser motors you can set correct compensation direction for the servo here.

Gear Settings - Sensing Divider

Electric motor: Motor poles / 2. For a 10 pole motor set divider to number 5. Mostly configured to 3 – 5.

Nitro/Gasser motor: Number of all active magnets. Mostly it is 1 – 2.

Gear Settings - Gear Ratio

Gear Ratio of the helicopter between the main wheel and pinion of the motor. For example: 120T main gear / 12T pinion = 10.

Max. Head Speed

Configure max. head speed that should be achieved with 100% throttle curve. For example: If you know that you won't exceed 2500 RPM then you can set the value to 2500. With 80% throttle curve your head speed will be 2000 RPM (2500 * 0.80 = 2000).

Fine-Tuning – Spoolup rate

Configure speed of the motor spoolup. For initial tests we recommend Slow spoolup rate.

Fine-Tuning – Spoolup Rampup

Value that will be added at the beginning of motor spoolup – when Hold is turned off. If the spoolup is not smooth, i.e. motor will start with a kick, the value is too high. If the spoolup has a delay, the value is too low. Default value of 50 μs should work fine in the most cases.

Fine-Tuning - Governor Response

This parameter is the most important one to achieve fast and proper response of the governor. It determine how fast the governor should react to a short-term load. Thus optimal settings are required. If configure too low or too high, rudder will not hold properly and can oscillate. Governor can greatly affect rudder performance so you can achieve better holding behavior. Too high value will result in overspeeding during e.g. pitch pump.

Fine-Tuning - Holding Performance

Determine how well the head speed is maintained during a long-term load. If value is too low then during e.g. tic-toc maneuver head speed can drop gradually. In case it is too high then after the tic-toc head speed can be higher than necessary and can even return to requested RPM with noticeable delay. It is better to start governor tuning process with low value.

Fine-Tuning - Holding Limit

Prevents from prolonged overspeeding after demanding maneuvers. If head speed is higher than requested after demanding maneuver then by decreasing percentage value it is possible to shorten or eliminate this odd behavior. If Limit value is too low then Holding Performance will not affect Governor performance. It is recommended to use 80% for the most helicopters. Usually combustion helicopters might need to decrease the Limit. Changing the Limit as the last parameter of the Governor is recommended - once a proper Governor Response and Holding Performance values are configured.

7 Transmitter

Flat Throttle Curve above 50% is necessary in order to use Governor feature. Under 50% Governor is immediately disarmed and instead motor will be driven directly by throttle curve. As soon as it will exceed 50% spoolup procedure is engaged until Requested RPM is reached. Only when Flight log will show Governor was Engaged then Governor is maintaining Head-Speed. If this message is not present it mean that Governor is still in the spoolup procedure.

In order to achieve different Head Speeds on demand you can set different flat curves (for example for each flight mode).

Governor can be deactivated in flight by switching to a Bank where Governor is disabled in the Spirit Settings. It can be also re-activated by switching back to a Bank with enabled Governor.

For a Combustion motors we recommend to go from Idle RPM (Throttle Curve around 10%) directly to 50% flat curve and above. This will trigger smooth spoolup.

8 Fine-Tuning Procedure

Firstly you have to finish basic setup including Max. Head Speed. Throttle curve in the transmitter must be FLAT. We recommend to set the throttle curve for example to flat 70%, 80% or 90%.

After disarming Throttle Hold you should immediately see Requested RPM in the software – this is desired head speed that should be maintained. Current RPM is head speed that is currently on the rotor head. If Current RPM is not calculated properly, then there is a problem with Gear Settings. In case that you can see zero or random Current RPM value then there is a problem with RPM Sensor and must be fixed.

Performance tuning procedure

We recommend to set the following values for the beginning:

- Governor Response: 5

- Holding Performance: 1

- You should start with increasing the Governor Response. You can do so until RPM is constant enough while doing aggressive collective pitch changes during hovering. When you will notice an overspeeding (RPM is higher than initially was) then the value is too high. In case that the value is too low or too high then the rudder performance can be affected negatively as well.

- When the Governor Response is well tuned, you can continue with increasing the Holding Performance parameter. In case that the value is too low, you will notice poor holding performance during demanding maneuvers with longer duration such as loop or tic-toc. If the value is too high, you can observe that the head speed is unstable even during stationary hovering.

Governor Response: 6 and Holding Performance: 5 may work fine for wide range of the helicopters.

- Throttle calibration of the ESC is possible only if the Governor is disabled in the unit.

- For throttle curve under approx. 50% governor is inactive – throttle is controlled directly.

- You should see “Governor was Engaged” event in the log after spoolup with enabled governor.

- Governor Bailout function can be activated whenever the throttle signal is higher than 1250 μs which is approx. 12% throttle curve. If the signal is lower then smooth spoolup sequence is activated.

- In case that the Current RPM value is 8000 RPM measurement is out of range. It may be needed to change count of the active magnets.

- If governor does not react correctly during Throttle Curve changes or even during spoolup, it is most probably result of an excess noise in the RPM sensor or connection. You may consider to use a proper shielding. Increasing value of the RPM Sensor filter in the Expert settings can solve the problem.

9 Autorotation Bailout

For those pilots that are performing autorotations the Bailout feature can be usefull. This feature allows to spin-up the motor to the flight RPM quickly when needed. You can change the Autorotation Bailout rate in the Advanced/Expert settings.

In order to make it work you only have to set your transmitter.

- When doing autorotation do not engage the Throttle Hold.

- Use an assigned switch instead, that will set the Throttle Curve to somewhere between 12 - 50%.

If Throttle Curve will drop under 12% the spoolup will be normal.

10 Throttle Hold for Autorotation (optional)

In case that you want to use only Throttle Hold for autorotation, please perform the following steps:

- Set the Throttle Curve for Hold to 12%. (This will spin-up the motor)

- Decrease General/Governor/Throttle Range - Min. until the motor will stop completely.

- Increase the Spoolup Rampup until you will get immediate spoolup when Hold is disarmed.

11 Troubleshooting

- A delay between disarming Throttle Hold and motor rotation - motor will start to spin after a short time.

- Make sure that your Throttle Range was configured correctly. Did you calibrated the throttle range with the Spirit connected?

- We recommend to put the ESC into the Factory settings. In the most cases the default range is matching with preconfigured range in the unit (1100μs - 1900μs).

- In case that the range is configured correctly, but there is still a noticeable delay, please increase the Spoolup Rampup parameter until the motor will start to spin instantly after disarming the Hold switch.

- Motor will kick after disarming the Hold switch causing unwanted rotation of the model.

- Decrease the Spoolup Rampup parameter until the kick will disappear. If you will notice a delay before spooling, the value is too low now and other solution must be used. In this case the problem cannot be solved by any settings of the Spirit unit.

- Check if the ESC supports a Spoolup Power parameter. If it is supported, then try to decrease the power and observe if it will help you. In some cases a different Timing or PWM frequency can help, but always make sure that the settings are valid for your motor.

- After demanding maneuvers the head speed is maintained at higher RPM for prolonged period.

- Verify that the Throttle Range of your ESC or Throttle servo is configured properly. Usually the problem is caused by exceeded limit for the full throttle defined by Throttle Range - Max. value. For example, if the top limit in the ESC is programmed to 1800μs but the unit has configured 1900μs, then the unit will be 100μs over the real limit. Thus during a high load it could take a few seconds until the value will drop under 1800μs in this case.

- Correct solution is to reconfigure the Throttle Range either in the ESC or in the unit.

- There is often "RPM Sensor data are too noisy" event in the flight log.

- Make sure that the connection of the RPM Sensor output is good. If the RPM Sensor is separated from the ESC, please connect its power supply (especially the grounding wire) as close as possible to the RPM signal wire in the unit. Usage of a ferrite rings for the power supply could reduce a noise as well. Verify operating voltage requirements for the sensor. Some sensors require 3.5V or more so they can't be powered from the Spektrum port of the unit. In some cases it is caused by too high Governor Response value, because motor will start to jitter.

- Governor is not switching between different throttle curves.

- Your Throttle Range in the ESC is calibrated incorrectly - range that unit is programmed for is not matching range of the ESC. Correct calibration of the range will solve the problem.

- RPM signal was lost.

- If Governor will loose the signal, it will detect the event within 2 seconds. Governor will still work, but with worsened performance - similarly as with a V-curve. This event can happen, if the signal cable connection will fail. For this reason we highly recommend to use a hot glue or other way for securing the connections.