Configurazione

La configurazione viene eseguita utilizzando il software, che combina efficienza e semplicità offrendo parametri regolabili, inclusi parametri avanzati.

Il software offre l'installazione guidata. Si consiglia vivamente di utilizzare il procedura guidata in quanto ti guiderà attraverso l'intera configurazione dall'inizio al il primo volo.

Contents

1 CONNESSIONE AL PC

Prima di iniziare la configurazione vera e propria è necessario collegare il sistema a un computer tramite una porta USB. A seconda del sistema operativo e computer, potrebbe essere necessario installare un driver dopo aver collegato il cavo a Porta USB.

Le impostazioni dello spirito sono disponibili per i seguenti sistemi operativi:

- Microsoft Windows

- Apple OS X

- GNU/Linux

- FreeBSD

Una volta connesso e installato con successo il driver, una nuova porta COM virtuale dovrebbe essere visibile nel software e in Gestione dispositivi.

MICROSOFT WINDOWS

Installa il driver tramite il programma di installazione del software. Questo processo sarà descritto in a

sezione seguente.

APPLE MAC OS X

Per una corretta funzionalità è importante scaricare e installare il driver da

il seguente URL:

OSX - 10.12

OSX - 10.13+

GNU/LINUX & FreeBSD

Non è necessario installare nulla.

1.1 WIFI-LINK

Il software Spirit Settings può essere connesso al modulo Wifi da ora. Si chiama "Spirit Wifi-Link" ". Wifi-Link può sostituire completamente l'interfaccia USB. Così l'utente può eseguire tutte le impostazioni in modalità wireless. È possibile trovare la descrizione della connessione nella pagina delle istruzioni Wifi-Link.

2 COLLEGAMENTO CON L'UNITÀ

Se hai già collegato l'interfaccia USB al tuo computer, avanti collegare il cavo di interfaccia alla porta 'SYS' dell'unità Spirit FBL. L'unità Spirit FBL non può essere alimentata dal cavo USB / porta SYS, quindi lo è necessario per alimentarlo dal ricevitore, da un BEC o da una batteria esterna pacco. Le porte RUD e AUX vengono utilizzate per alimentare l'unità Spirit FBL e se si utilizza un BEC o batteria si consiglia di collegarsi a queste porte con una tensione tra 3V e 15V. Il filo centrale deve essere il collegamento a tensione positiva.

Non collegare mai un connettore per alimentare l'unità alle porte SYS o ELE / PIT / AIL.

Se l'unità non è ancora configurata (ad esempio una nuova unità) si consiglia di non collegarsi tutti i servi ancora.

3 INSTALLAZIONE SOFTWARE

Di seguito sono riportate le istruzioni di installazione per le piattaforme supportate. Il software di configurazione è disponibile sul sito web di Spirit System: spirit-system.com.

MICROSOFT WINDOWS

Esegui il programma di installazione e segui la procedura guidata.

Se il driver non è ancora installato, ti verrà data la possibilità di farlo durante il

processo di installazione.

Il programma di installazione eseguirà tutti i passaggi necessari per preparare il computer

per eseguire il software di configurazione. Al termine dell'installazione

processo, il software di configurazione può essere avviato dal desktop o

elenco dei programmi, chiamato "Impostazioni spirito".

Per una guida dettagliata all'installazione, al lancio e alla risoluzione dei problemi di Spirit Settings, apri la pagina Spirit Settings in Windows.

APPLE MAC OS X

Installa il software scaricato aprendo il file DMG e quindi spostando il file

contenuto nella cartella Applicazioni. Il software di configurazione può essere avviato da

la cartella Applicazioni con "Spirit-Settings".

GNU/LINUX a FreeBSD

Estrai tutti i file dall'archivio scaricato, ad esempio, nella tua casa

directory.

Il software di configurazione può essere avviato dalla directory appena creata

con il file "settings.sh".

La guida all'installazione di Linux Mint (o compatibile) è disponibile nella pagina Spirit Settings under Linux.

4 AVVIO DEL SOFTWARE

Una volta installato il software, assicurati che la tua unità Spirit sia collegata tramite USB a la porta SYS, accesa e inizializzata (le spie LED sono accese), quindi eseguire il software sul tuo computer.

Avvia le impostazioni dello spirito dal desktop o da una directory in cui è stato installato.

Il software di configurazione dovrebbe essere avviato dopo che l'unità è stata inizializzata. Ogni volta che Spirit FBL viene inizializzato (il LED di stato è acceso) e connesso, puoi farlo apportare modifiche alle impostazioni. La configurazione durante il volo non è possibile a causa dei rischi per la sicurezza associati.

PROBLEMI SU WINDOWS

Se il software di configurazione non è in grado di rilevare una porta COM valida, puoi provare

avviare il software come amministratore.

In alternativa, controlla il numero della porta COM. Se il valore è troppo alto prova

riconfigurando il numero di porta (dispositivo Silabs) su, ad esempio, COM1 - COM4.

Per i notebook vale anche la pena disabilitare qualsiasi funzione di risparmio energetico USB in Dispositivo

manager.

Per vedere come installare correttamente il software, visitare la pagina Impostazioni dello spirito in Windows.

PROBLEMI SU MAC

Se il software di configurazione non è in grado di rilevare l'interfaccia USB, assicurarsi che il Driver sia installato.

È molto importante che la versione sia corretta altrimenti può portare a instabilità.

PROBLEMI SU LINUX

Per vedere come installare correttamente il software, visitare la pagina Impostazioni dello spirito sotto Linux.

5 UTILIZZO DEL SOFTWARE

Dopo il collegamento riuscito dell'unità Spirit FBL, tutte le funzioni di configurazione dovrebbe essere accessibile. In caso contrario, prova a scegliere un'altra porta COM (dispositivo) o provare a riavviare il software, scollegando l'unità dall'alimentazione e ripetendo la procedura.

Assicurarsi che il software venga avviato dopo che l'unità è stata inizializzata.

5.1 TAB. CONNESSIONE

Questa scheda indica lo stato corrente della connessione, ti informa sul versione corrente del firmware, visualizza il numero di serie del collegato e consente di cambiare la porta COM. Inoltre è dotato di una procedura guidata per la configurazione iniziale.

Ti consigliamo di utilizzare questa procedura guidata, poiché ti guiderà attraverso una configurazione di base nel modo più semplice e semplice.

5.2 GENERALI

Se hai già impostato l'unità utilizzando la procedura guidata, puoi crearne altre regolazioni alla configurazione qui. Tutti i valori si riferiscono alle impostazioni selezionate in il wizard.

Ogni volta che i parametri vengono modificati, il nuovo valore viene immediatamente applicato ma non salvato. A meno che le impostazioni non vengano salvate manualmente, dopo aver scollegato l'alimentazione fornire tutte le modifiche non salvate andranno perse. (vedere la scheda Backup.)

Posizione

Seleziona la posizione in cui l'unità è attaccata al modello.

(Vedi sezione 3 - Installazione)

Piatto oscillante

Seleziona il tipo di swash del tuo modello.

Nella maggior parte dei casi è CCPM 120 ° o CCPM 120 ° (invertito).

Qualsiasi miscelazione di sciabordio nel trasmettitore deve essere disattivata. Deve essere configurato sul tipo H1 (servo singolo).

Ricevitore

Seleziona il tipo di ricevitore che stai utilizzando:

- PWM – ricevitore standard.

- PPM – collegamento a linea singola.

- Spektrum DSM2/DSMX – Satellite DSM2 o DSMX o ricevitore SPM4649T. (per Spektrum integration).

- Futaba S-BUS – ricevitore collegato tramite SBUS. (per Futaba telemetry)

- Jeti EX Bus – ricevitore collegato tramite EX Bus (per JETI model integration).

- SRXL/SUMD – ricevitore collegato tramite SRXL, SUMD, UDI (per HoTT integration).

Stile di volo

Imposta il comportamento del modello in volo.

Questo parametro viene utilizzato per controllare e adattare il comportamento di volo in base al

requisiti del pilota. Ha un impatto significativo sulle manovre piroettanti (governo ciclico), ma non sulle stesse piroette (timone).

Il parametro non ha effetto su una stabilità. Generalmente, per i modelli più grandi si consiglia un valore più alto.

Valori più bassi significano che il modello si comporterà in modo più coerente, modo controllato e si sentirà più lineare e robotico. Potrebbe introdurre un ritardo nello sterzo. Il momento angolare sarà mantenuto più costantemente.

Higher values mean a more natural behavior. The response to stick movements will be more flybar-like where fast movement will introduce agressive response. But a small movements near the center will be more precise. It can help to make tic-tocs faster. End of each cyclic input will become faster.

Recommended value for the most pilots: 4.

Channels

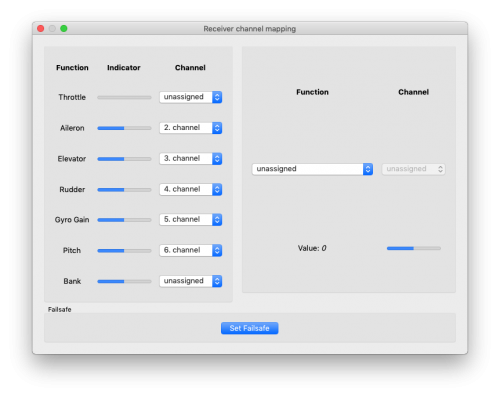

After clicking the button, the window with channel assignment is displayed.

You can assign any channel to any function here. The number of available

channels is dependent on the receiver type. Remember to only assign one

channel to each function.

When a channel for Throttle function is assigned, throttle output from the unit

can be obtained from the AUX position.

When a channel for Bank function is assigned, then Bank switching is activated

(See chapter 5.6).

When a channel for Gyro Gain function is unassigned, it is possible to configure

gyro gain directly through this software in Sensor tab. The unassigned channel

could be used in another way, e.g. for Bank switching.

Failsafe

For a PPM, Futaba S-BUS, Spektrum DSM2/X, Jeti EX Bus, SRXL/SUMD receiver types you

can set the Failsafe directly in the unit. Channel values are stored

immediately after clicking the Set failsafe button. In case that the signal is

lost for more than 1 second it will set the values automatically in the flight.

With other receiver types the Failsafe is programmed in the transmitter or receiver.

Realtime tuning

By assignment of a parameter (P) it is possible to change the settings directly from your transmitter.

You can comfortable set selected parameter by changing channel value (for example by a potentiometer).

Thus you do not need a configuration software at all. Usual transmitter is enough.

A change in corresponding channel will immediately change value of the parameter. Maximal deflection will set the highest value of the parameter, while the minimal deflection will set the lowest value.

Realtime parameter tuning has the highest priority. So when enabled, saved value from the profile or a Bank will be ignored.

This functionality is enabled only when the configuration software is not connected. This will prevent from a possible collisions. As soon as the software is disconnected, selected parameter is configured by the channel value. In case that the software is started again, it will keep value from realtime tuning in it's memory. However, with opened software policy described above will be applied again (Realtime tuning is inactive and value will be intact even if channel is changed).

You can configure 3 different parameters and functions simultaneously with this feature.

If function (F) is assigned, it is engaged when it's value is equal to 1. Vibration analysis function allows you to measure vibrations during the flight. It is described later in the Diagnostic tab section.

When parameter tuning is complete, it is recommended to open the software and save the settings to the unit. Then unassign the parameter so the value can't be changed anymore.

It is recommended to always carry extreme caution to not loose control of the model!

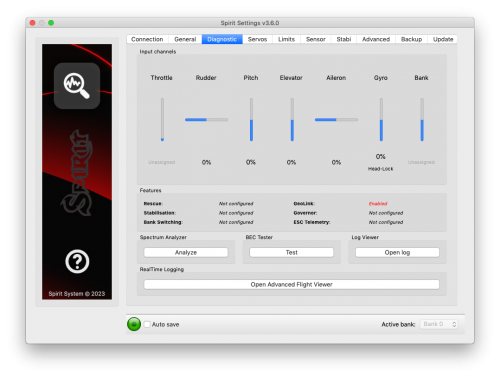

5.3 DIAGNOSTIC TAB

Once the settings in the previous tab have been completed, it is now recommended to make any adjustments and changes required in the transmitter so that the transmitter controls match the displayed system's outputs. Generally, each transmitter is different and the center of the channel is never exactly the same. Wear and environmental influences can also have an effect causing the center of the channels to fluctuate. Another consideration is the maximum and minimum value of each channel. Here, you adjust your throws using your transmitter's servo endpoint adjustments.

For a proper operation of the unit, it is necessary that movement of each channel correspond with the bars. Direction of the movement must match with the sticks as well.

Secondly, it is necessary to check the values of aileron, elevator, pitch and rudder channels. These channels must be centered at approximately 0%. The unit automatically detects the neutral position during each initialization. Do not use subtrim or trim functions on your transmitter for these channels, as the Spirit FBL unit will consider these as an input command.

Ensure all subtrims and trims are zeroed.

It is also recommended to set the maximum and minimum values. Test the minimum and maximum throws for all channels, if these values are not equal to -100% and 100% in the diagnostic tab it is necessary to adjust your transmitter endpoints to correct this.

After these adjustments, everything should be configured with regards to the transmitter. If some channels oscillate around the center, it may mean wear of the transmitter potentiometers. This can be compensated for by increasing stick deadband in the Advanced tab. (Covered later)

If the values in the aileron, elevator, or rudder channels are shown in bold, the system is recognizing a command to move/rotate the axes.

To determine Gyro Gain and Mode of the rudder gyro you can check Gyro bar.

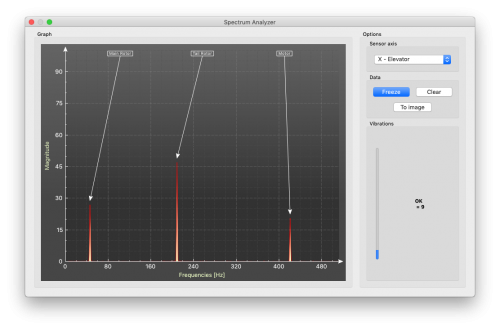

SPECTRUM ANALYSER

The Spectrum analyser is a tool for measuring the amount of vibrations on your model. It is a diagnostic tool designed to determine which rotating part is causing a problem. With this information you can easily identify and fix any problems with your model.

To check condition of the model you can see "Vibrations" bar. This indicate general vibration amplitude in selected axis.

It is possible to measure vibrations in three separate axes:

- X - elevator axis

- Y - aileron axis

- Z - rudder axis

- In-Flight - flight vibration player

The live graph shows frequencies for the currently selected axis. This enables you to see both the frequency and magnitude of the vibration on the selected axis.

Vibrations are transmitted to each axes dependent on several, various factors. Frequencies and magnitude are dependent on the model construction. Generally, the vibrations are the highest on Y axis (aileron) but we recommend you check all axes each time you are doing measurement. However vibrations should not exceed 50% for all axes at any time. In the case vibrations are at 90% or more, the model has an issue that needs to be rectified. Should the magnitude exceed 90% on any of the given axes, it is recommended to fix whatever issue is causing these extreme vibrations before flying the model. Even though Spirit FBL unit is highly resistant to vibrations, these could cause unwanted interactions with the Spirit FBL unit and could also cause mechanical failure of the model. Such high vibrations can cause Loctite to fail and other mechanical parts to break.

Vibration levels:

- Vibrations up to 50% - vibrations at a normal and acceptable level

- Vibrations between 50% and 90% - raised vibration levels

- Vibrations exceeding 90% - extreme vibration levels

As well as overall vibration levels not exceeding 50%, any specific frequency (peak) should not exceed 50%. Anything above this level should be cause for concern and requires further investigation.

For comparing the graphs, you can use the Freeze button. The current live graph is displayed and the graph captured using the Freeze button is saved and will be displayed as subgraph. This graph can be deleted with the Clear button.

It is possible to save the Spectrum analyser graphs. Using the To image button, the current graph will be saved as an image.

The Spectrum analyser is able to detect the vibration frequencies up to 500Hz (rotating parts at speeds up to 30,000 RPM).

Measurement procedure

- Remove main and tail blades from the model.

- Place the model on a suitable, soft surface (e.g. carpet, grass).

- Set blade pitch at approximately 0° on both main and tail rotors.

- Run the Spectrum analyser (this also freezes all servos).

- Spin up the motor to the usual flight RPM.

- Switch between the X, Y and Z axes, saving an image of each.

- Check vibrations in all axes.

- Stop the motor.

Recognizing vibrations

To recognize which component or part is causing abnormal vibrations it is necessary to determine the speed of the highest peaks. The main rotor will have the lowest speed and the tail rotor speed will be approximately 4.5x higher. Generally, the smaller the size of the model, the higher the headspeed will be.

In order to find out which part of the model is causing the unwanted vibrations, move cursor to the peak and check the head speed (RPM). The speed of the main rotor is usually in the range of 1500 to 3500 RPM. Therefore, if the speed is within this range, it is likely that there is a problem with the main gear, main shaft, main shaft bearings or rotor head itself.

Most excessive vibrations are usually, although not always, tail related. To check if there are vibrations coming from the tail you should find the frequency peak that is approximately 4.5x higher than the frequency of the main rotor.

Once you identify which part of the helicopter is causing the unwanted vibrations, you can gradually remove components of the suspect assembly, repeating the measurement process until the vibration disappears. Once the vibration levels have dropped to an acceptable level, you have found the suspect component and can replace it.

Measuring with tail blades installed carries some safety concerns and will also show increased levels of vibration.

Gasser motors shouldn't be operated without load! Vibration measurement can't be performed without blades.

In-Flight - vibration analysis from flight

This feature allows you to record vibration spectrum from any moment of the flight. By selected channel you can tell the unit when the spectrum should be taken. The spectrum can be later viewer in the Spirit Settings software with the In-Flight option in the Diagnostic/Spectrum analyzer. Saved vibration spectrum will be stored until unit will lost the power. Saved record is rewritten on repeated activation.

For vibration measurement in the flight set the Special function in the General/Channels. Assign function F: Vibration analysis with axis you want to measure. Then select a channel which will be used for activation of the function.

As soon as the value is equal to 1 the vibration spectrum is saved. The record is saved exactly at the moment when function will change it's state from 0 to 1.

During flight it is enough to change state of selected switch of your transmitter (for example 2-state switch). After landing you can connect unit with the software and open the Vibration analyzer (select In-Flight axis to display the spectrum).

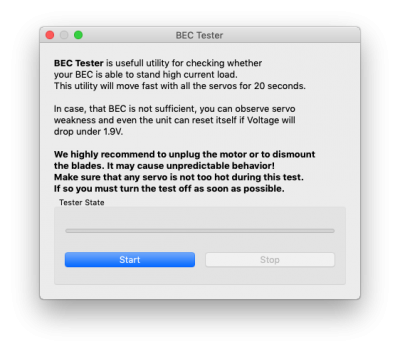

BEC TESTER

The tester is used for determining whether your power supply for the unit, receiver and servos is sufficient. The purpose is to achieve the biggest current spike and verify that your supply voltage will not drop under the safe level.

Click the Start button to start the test. After 20 seconds it should be finished.

If you will observe any issue, then your power supply is insufficient and should not be used. In this case power supply with higher current rating should used.

LOG VIEWER

The log is used to record events during flight. If a problem occurs and the reason isn't immediately known or evident, checking the log can help in identifying the issue.

It works in such a way that it records various events from the time the unit is powered on. If an event occurred you can see this in the log, reporting to the log is done every 10sec. When you click the Open log button you can see the current flight log which contains all the events from the last flight. When the power is disconnected, the log is cleared.

In the case of a major problem occurring during the flight ![]() , the log is then saved permanently to the unit's memory and remains there until such time as the log is opened.

If there is a saved log in memory, the user is advised with the message “Log from previous flight is available!” and the log from the flight when the problem occurred is opened. For example, when a signal is lost or the power supply failed you can find this in the log. The log from the first flight where the major problem occurred is always saved. If this is not opened, then it will not be overwritten with a newer one. In this state, the user is also notified by different cyclic pitch pump during the initialization process - elevator servo will change it's movement direction.

, the log is then saved permanently to the unit's memory and remains there until such time as the log is opened.

If there is a saved log in memory, the user is advised with the message “Log from previous flight is available!” and the log from the flight when the problem occurred is opened. For example, when a signal is lost or the power supply failed you can find this in the log. The log from the first flight where the major problem occurred is always saved. If this is not opened, then it will not be overwritten with a newer one. In this state, the user is also notified by different cyclic pitch pump during the initialization process - elevator servo will change it's movement direction.

The log can contain the following events:

- The model is in good condition. The unit did not recognize any problems.

-

- Sensor calibration was successful.

-

- Governor achieved requested RPM and is active from this moment.

-

- Cyclic achieved its maximum tilt angle. This indicates the model was unable to do the desired correction as necessary. In most cases it is not relevant. But it is possible that the value of the Cyclic Ring parameter is too low and the model can't rotate as fast as intended in the aileron/elevator axes. Alternatively, a too high value for rotational speed could be configured. It is also possible that in fast forward flight the model can pitch-up rapidly. We recommend to set this parameter as high as mechanically possible.

-

- The rudder servo reached its configured limit. When this event occurs before or after a flight it is not a problem. If you see this during flight it indicates that the rudder did not operate correctly. In most cases it is visible during flight as poor rudder response or “blow out”. If the model is set up correctly then it could be due to low rudder efficiency such as the tail blades being too short or headspeed too low. There is also the possibility of a mechanical issue or with the rudder limits being inadequate.

-

![]() RPM Sensor data are too noisy:

RPM Sensor data are too noisy:

- RPM readout is very unstable and are oscilating more than +/- 100 RPM. Data from the sensor are unusable for the Governor. Use additional shielding and mount a ferite rings. Increase value of the RPM Sensor filter parameter in the Expert settings.

-

- Received frame is unusable and will be ignored. In the most cases it does not present any problem. If the event is occuring often, then connection between receiver can be wrong or there is excess noise. Verify quality of the link and check the cable between unit and receiver.

-

![]() GeoLink function is imprecise:

GeoLink function is imprecise:

- GeoLink feature is not functioning properly. GeoLink Compass might require new calibration. Make sure there are no nearby motors, servos or magnets near the module.

-

- GeoLink communication quality is imperfect. Verify cable between GeoLink and Spirit unit. Make sure there are no static discharges coming from a belt. Use the shortest possible cable.

-

- Sensor data reading failed - RPM sensor malfunction probably occured. Sensor is not sending data for 2 seconds or longer. Make sure, that the sensor wiring is correct and that the motor is spinning when Hold is disarmed.

-

- Signal lost suddenly. This problem should not occur at any time and must be resolved before the next flight. There could be a problem with the receiver and/or transmitter antennas. It could be a faulty receiver cable or the connection between the unit and receiver. In some cases signal loss can happen because of electrostatic discharge caused by static build up, this usually occurs in belt driven helicopters.

-

- The main loop was delayed. This can happen when wiring is incorrect or there is abnormal electrical noise interference with the unit, for example, from a BEC. If using the configuration software it could mean the link to the Spirit FBL unit is slower than it should be.

-

- Power supply voltage is lower than 2.9V. This mean you have to use a BEC that is capable of handling higher loads. In rare cases it could be faulty connections in cables.

-

- Vibration level achieved the level that is not normal and can affect integrity of the helicopter. During hard 3D maneuvers the event can occur more frequently.

-

- GeoLink module communication stopped unexpectedly. All GeoLink features will be unaccessible. Please verify cable between GeoLink and Spirit unit. Make sure that GeoLink LED light is not flashing after landing.

-

All reviewed logs are saved as PDF files into Documents directory.

5.4 SERVOS TAB

This tab is used for servo configuration, care should be taken to ensure correct frequencies are used and that the directions are set correctly.

Type

In this section, set the values for neutral pulse and frequency according to your servo manufacturer specifications.

For analog servos the frequency is usually a maximum of 60Hz.

Subtrim (tuning)

Ideally, without the rotor head installed, use a swash leveler to align the swash and servo horns so that the swashplate and servo horns are horizontal and perpendicular to the main shaft.

This is done by ticking the item Subtrim (tuning). This will put the Spirit FBL unit into a special mode where the collective position will be neutral with the servos centered. In addition, stabilization will be disabled.

Servos can easily be adjusted at this time. When completed, the swashplate should be exactly perpendicular to the main shaft and in addition collective pitch should be at 0° (it is possible to measure the pitch angle using a pitch gauge with rotor head and blades attached).

In most cases, it is also necessary for servo horns to be perpendicular to the main shaft. All servos, i.e., CH1, CH2, CH3 and CH4, are set separately on individual sliders. CH1 and CH3 are the aileron servos. CH2 controls the elevator and CH4 controls the rudder.

It is also necessary to set the subtrim and mechanics of the rudder so that the servo horn is perpendicular to its case and rudder pitch is at 0°. This setting will affect rudder stop performance.

Once set up, un-tick the Subtrim (tuning) check box to turn off this special mode.

After exiting the special mode, stabilization and rudder will work again. Be sure your collective pitch channel is configured correctly in the transmitter. That means you should see -100% to 100% in the diagnostic tab. Double check that 0% in diagnostic tab corresponds with middle position of your collective/throttle stick (with linear -100% - 100% collective pitch curve).

Micro helicopters and µSpirit: When Tail rotor is driven by a dedicated motor, the Rudder ESC performance can be noticeably improved by configuring Low RPM value to achieve the lowest spinning RPM for the Tail rotor. This can be configured by Subtrim (CH4) - Low RPM - the value has impact on lift off and symmetrical turning performace.

Servo reverse

This allows you to choose which servos should have their direction of motion reversed. While changing the collective pitch all servos should move in same direction. After this settings the model should react correctly to the sticks movement.

This parameter is the most important!

Servo travel correction

Here, you are able to modify and correct travel for each servo individually. Some servos are not very accurate in regards to travel at their limits and this inaccuracy may have a negative impact on flight characteristics. Once in this section of the software, the unit switches to a mode for doing these corrections.

It is expected that in the previous step, Subtrim (tuning), the swashplate was set at zero collective (0° rotor blades pitch). The procedure is such that you should use a swash leveler to determine whether there is any deviation on any of the servos in the lowest and highest points of collective throw. For both positive and negative positions, it is necessary to set the values separately – this is the reason for 6 sliders. If the travel is less than required, increase the value. If too much, decrease. To activate sliders in the secondary part move your collective to opposite direction.

This correction is also useful if there is asymmetric geometry on the helicopter causing issues such as the inability to achieve equal positive and negative pitch values. In this case, it is necessary to modify the positive or negative sliders for all three servos. If you are unsure about your settings, it is better to leave the sliders in the Middle. (position 0)

5.5 LIMITS TAB

This tab affects limits and servo travel ranges.

Cyclic Ring (tuning)

This parameter sets the electronic cyclic ring, which allows the model to achieve the largest cyclic ranges without mechanical binding (binding of servo horns, pushrods and linkages).

The settings here should be done very carefully to avoid damage to the model or it's associated electronics. Never exceed recommended angles by manufacturer of the model, otherwise a boomstrike can occur.

First, set your desired Collective range, for example, +/-12°. We recommend

using a -100% to 100% linear collective pitch curve in the transmitter.

Now it is time to set the Aileron/Elevator maximum cyclic pitch range.

Try to set the largest possible deflection. Generally the Cyclic pitch angles (range) should be equal or lower than Collective pitch.

This parameter does not directly affect the speed of rotation, but if it is too low, the model may not have consistent pitch and roll rates.

The setting should be done with 0° collective pitch. Then carefully move with sticks in all directions to ensure that mechanical binding

does not occur. This should also be done for the maximum and minimum Collective pitch.

If you increase the collective pitch range, this parameter must then be

checked and in some cases adjusted to ensure no binding occurs at your new

maximum and minimum pitch ranges.

If the selected cyclic ring range is insufficient, it is possible that pitch-up can happen during fast forward flight (even if the pitch-up compensation is at its maximum value). This is because the model will not be able to add sufficient corrections with the configured range.

Rudder end-points (tuning)

Left / Right limit - Sets the minimum and maximum deflection of rudder rotor blades.

We recommend setting these values for both directions to the maximum

allowed range by the manufacturer of the helicopter. Otherwise, the rudder

may not be able to keep the yaw direction during demanding maneuvers and

tail blow outs may occur.

Do not exceed allowed limit for your model.

Micro helicopters and µSpirit: When Tail rotor is driven by a dedicated motor, the Rudder ESC must be connected at the CH4 port. Rudder end-points are then used to set available Throttle range for the Rudder ESC from 0% (Stop) to 100% (Full). We recommend to set Stop limit to 126 and Full limit to 150 for the beginning.

5.6 SENSOR TAB

This tab is the last important part of the settings which must be configured.

Sensitivity

The rotary dial adjusts the gyro sensitivity for aileron, elevator and rudder axes.

Cyclic gain – The higher the value is, the higher the accuracy within the control loop. The default value is preconfigured to 55% gain, for most models an optimal value of around 60% is suggested.

Rudder Common Gain – 1.00x means no multiplication. This is the recommended value for 550-class helicopters and smaller. For bigger helicopters it is often higher. 1.3x could be fine. Gyro Gain in your transmitter should be configured to approximately 50% for the first flight.

Rudder Gain – This parameter is enabled only in case of unassigned Gyro Gain channel. It replaces function of Gyro Gain from the transmitter, so you can directly set the value in the software.

Rudder Gain in the software or in your transmitter can be programmed in this way:

- Head-Lock mode: 1% to 100%

- Normal (Rate) or a special function: -100% to 0%

Negative gyro gain can be used to activate the rescue or the stabilisation modes – check the Stabi tab.

Some transmitters have a gyro range of 0 to 100% where 50% is the middle - zero gain (e.g. Spektrum DX6i). Others use a range of -100% and 100%, where 0% is the middle.

Rotation speed

The default value is 8 and will favor beginners more, the higher the value, the faster the rate of rotation. This factor also depends on the mechanical linkage ratio or D/R (Dual Rate) in the transmitter and also on the Aileron/Elevator limit.

Make sure the value is not too high else it can cause unwanted and inprecise movements.

default value - 8

We recommend to set the Cyclic rotation rate within a range of 8 - 11. Remember that DFC rotor heads tend to rotate faster so it's better to initially start with a lower value for them.

For the Rudder rotation rate pilots are preferring a range of 9 – 11.

5.7 STABI TAB

The Spirit unit offers you the options of model stabilization and rescue mode.The stabilization function, once activated, will recover the model to a horizontal position without any other input from the pilot, this can be used as a “bail-out” feature when trying new maneuvers and can help with the learning process.

Rescue mode complements the normal operation of the Spirit unit. If activated, the model will recover to a horizontal position and add collective pitch as per the settings. This function can be used any time when the pilot loses orientation or control of the model.

As soon as pilot will disengage the rescue mode full control is regained immediately.

Stabilisation mode will maintain horizontal position of the model once sticks are released. Making flying very easy. Different behavior is available within our stabilisation modes. Collective pitch steering is unaffected with stabilisation.

How to setup the Rescue or Stabilisation is described in the Stabi mode page. There is also Setup Wizard for the Rescue available directly in the Spirit Settings. See Stabi tab when Function is set to Disabled.

You can activate selected Function by two different methods:

- Negative Gyro Gain

- Dedicated Channel

Negative Gyro Gain method is suitable for radios with low channel count (6 - 7). When you have available unused channel, method with a Dedicated channel is better and easier.

Currently selected mode is displayed in the Diagnostic tab.

Function

Here is where you select which mode should be activated at negative gyro gains.

- Disabled - Normal (Rate) gyro mode.

- Rescue (Normal) - Recovers the model to an upright horizontal position – skids always to the ground. This recovery mode is great for the beginners.

- Rescue (Acro) - Recovers the model to a horizontal position, inverted or upright, whichever is closer at the time of activation. For intermediatte and advanced pilots that are flying acrobatic manouvers.

- Stabilization (Normal) - stabilization mode - skids always to the ground. This mode is good for learning the basics such as hovering and slow transitions. Model is always pushed to the horizontal position.

- Stabilization (Acro) - stabilization mode - inverted or upright, whichever is closer at the time of activation. This mode is used for learning the basics of acrobatic maneuvers. If the sticks are in the center, the model has tendency for returning to the horizontal position.

- Stabilization (Scale) - stabilization mode - skids always to the ground. This mode is used for a scale flying. Gyro mode is Normal (Rate).

- Coaxial - stabilization mode - inverted or upright, whichever is closer at the time of activation. The steering behavior is very similar to a coaxial helicopters. Great for learning a hovering practices.

Rescue, stabilisation and GeoLink features can be affected by condition of the model. Before testing it in flight please see this page.

The rescue mode is very demanding for the BEC. Be sure your BEC can handle such peak loads. In case it is is not sufficient your model could crash! Never exceed angles recommended by manufacturer of the model, else the mechanics can be damaged during the flight!

Rescue collective pitch

This determines how fast the model will ascend during the rescue mode.

100% means the maximum deflection of the blades, which was configured in the Servos tab.

It is very important to check whether the rescue mode works correctly before the first flight (on the bench without the motor/rotors running).

Collective pitch should be always positive with the rescue engaged - while helicopter is on the ground

Sticks priority

Specifies the amount of control while configured mode is activated.

The higher the value, the more the model will react to stick movements.

Direction control rate

This specifies the rate of controlling direction for the stabilization mode.

Low values are well suited for beginners to get coaxial like behavior. Higher values are more appropriate for scale flying.

Acro Delay

Specifies a time period for the Rescue (Normal), when the model is recovered from the inverted flight. Until the period is reached, the rescue has the same behavior as the Rescue (Acro). In this way, faster ascending to a safe level can be achieved.

Rescue Duration

Once specified duration period will pass the Rescue mode will end and model will start to hover. For this purpose Hovering Collective Pitch value is used. The period is counted from time the Rescue mode was engaged. The parameter is available for both Rescue (Normal) and Rescue (Acro). Transition from Rescue to Hovering is smooth and will happen only if Rescue mode is still engaged. Collective Pitch control is returned to the pilot as soon as a pitch stick movement is recognized.

Hovering Collective Pitch

If Rescue Duration parameter is enabled and it will pass once Rescue mode was engaged the model will start to hover. To make the model hover it is necessary to set this parameter. If too low the model will be descending instead of hovering. If too high the model will be ascending instead of hovering. Value around 40% is recommended for hovering.

5.8 ADVANCED TAB

This tab is for more advanced configuration of the Spirit FBL unit. It is recommended that you fully understand these parameters before adjusting them. However, it is essential to set geometry. Other parameters, however, depend on the preferences of the pilot.

Geometry 6° (tuning)

For proper operation of the Spirit unit, it is necessary to set this parameter correctly. Here, the unit is switched to a special mode for settings 6° of cyclic pitch on the main blades. It is necessary to set the value so that the blades angle is at 6° in the aileron axis. You need to rotate your rotor head with blades to be parallel to the longitudinal axis of the model. A higher value increases the angle; a lower one decreases the angle. Optimal head geometry should be in the range of about 90 – 160. If not in this range, it is recommended to adjust the distance of a ball link on the servo horns or perform other mechanical adjustments.

Collective Direction

Parameter to determine direction of the collective pitch.

In case of a Trailing Edge rotor head or if a mixing arms are present on the rotor head, tick the Reversed option. In the most cases the parameter is unticked.

Correct configuration is very important, else the collective pitch will be reversed.

Elevator filter

This parameter compensates elevator bouncing during aggressive maneuvers. The larger the value, more compensation is involved.

If this value is too high it can lead to a soft feeling in the elevator. We recommend using the default value of 1 to begin with.

Cyclic feed forward

This parameter is used to set amount of direct feel between your sticks and

your model helicopter. The higher the value, the more aggressive the model

will feel and the faster the model will react to stick movements.

If the value is very high, elevator bounce-back effect can occur.

During a tic-toc maneuver you can also observe higher motor load or aileron oscillations, because the model is unable to react fast enough.

Setting this value too high can result in elevator bounce.

If the model feels disconnected and there is a lag between stick inputs and

the model, try increasing this value.

Rudder delay

This is parameter to smooth out a rudder movements. It also helps to stabilize the rudder – it is a kind of electronic damping, similar to a derivative term of regulation. The faster the servo is, the lower the Rudder delay should be. For analog servos it is recommended to set this value to around 20 - 25. For slower digital servos it is mostly between 10 - 15. For fast servos (~0.04s/60°) the value is around 5. In case of a brushless servos it is recommended to set the value of 0 - 2.

If the value is too high, the rudder could start to oscillate, wag or it could cause too smooth rudder stopping.

Rudder dynamic

If the rudder does not stop correctly, for example it overshoots, this behavior can be changed with this parameter.

6 – is the default value.

The larger the value, the more aggressive the behavior of the tail. If the tail overshoots in stops, the value is too high. This parameter also affects the response speed of the stick movement; a higher value means a faster response. If you cannot reach a symmetric stop on both sides you will need to make sure that the tail is centered at 0°. Alternatively, you can lower the rudder limit for that side.

Rudder – Revomix

Revomix (tail pre-compensation) adds rudder in response to collective pitch changes, when the tail needs increased holding. Revomix is independent of the transmitter. By default it is turned off, the user must set the amount required of the pre-compensation.

Allowed values are 0 to 10 with 0 being disabled; in most cases it is not necessary to use this parameter, however, when using low headspeed or on helicopters with a poor performing tail, this setting can be used.

Pirouette consistency

This parameter determines the consistency of pirouettes and holding performance. If pirouettes are not consistent during certain maneuvers, increase the value of this parameter.

This value is individual for every model, it depends on many factors such as: your rudder mechanics, head speed, etc. Before setting this parameter, it is recommended to first set the gyro gains.

If the value is too high, the tail can oscillate or wag. It can also cause poor stop performance. This value should be between 150 and 180.

For brushless servos it is recommended to increase value by 10-15 points.

5.8.1 EXPERT SETTINGS

For fine tuning you can set the following parameters. Normally it is not needed to configure any of these parameters.

Rotor Rotation Direction

Parameter to determine rotation direction of the main rotor. In the most cases it is in the clock wise direction - parameter is unticked.

Stick deadband

Determines the area, around center stick, where the system does not recognize any stick movement. If channel readings are inprecise the value should be increased. This can be verified in the Diagnostics tab. This parameter does not replace the Exponential function.

Elevator pitchup compensation

If, during fast forward flight, the model reacts to inputs too rapidly or if the model pitches up, increase this value until this no longer occurs. If the helicopter pitches up abruptly, this could be caused by a cyclic range that is too low and/or too much collective pitch. In this case, you will have to increase the Aileron/Elevator range as high as the model can handle without any binding. If this doesn't fix the problem, you can add more pitch-up compensation.

Cyclic phase

The value indicates the angle by which the swashplate is virtually rotated.

For example a value of 90 will rotate the elevator to aileron. This feature is recommended for models with multi-blade rotor heads. For most other models, we recommend a zero value.

Pitch Pump Booster

To achieve flybar-like collective pitch behavior, you can increase the value until desired feeling is achieved. Remember that higher values are too demanding for power supply and servos on the model.

Signal processing

This parameter is used for operation on models with extreme vibrations that can't be eliminated in any way. It should increase precision of the Rescue/Stabilisation/GeoLink modes if default settings are not satisfying. For example if Rescue or Stabilisation has a tilt upon engaging even after a basic maneuvers, please enable this parameter.

Flybar mechanic

If your helicopter is equipped with traditional flybar mechanics, you have to enable this parameter in order to use the stabilization or rescue modes. All settings are the same for flybarred helicopters except this parameter.

Flybarless helicopters must be configured and operated with the Flybar mechanic parameter disabled!

RPM Sensor Filter

In case that your RPM sensor has noisy output then RPM readout can be very unstable. This can lead to various problems with Governor. There may be a problem with spool up, flight mode switching or head speed jittering. To make RPM readout very precise, you may need to increase the value.

On the other hand, too high value can lead to a delay, that is unwanted for optimal Governor performance. So the value should be as low as possible while RPM readout is still precise. Variation of 1-20 RPM against the Requested RPM is optimal.

Autorotation Bailout rate

When performing autorotation the Bailout feature is available. The bailout is used to recover the headspeed faster than normally in order to achieve flying RPM. In this way pilot can regain full control of the model and continue in the flight. When using Spirit governor you can use this parameter to precisely set spoolup rate during the bailout. When Spirit governor is disabled, this settings has no affect.

Rudder - Control Type

With µSpirit units it is possible to enable support for the tail rotor driven by dedicated motor. In this case two ESCs are used, where Rudder ESC is connected at the CH4 port. Important thing is to set Limits/Rudder ESC - range appropriately since these are defining available Throttle range for the ESC from 0 to 100%.

Normally this parameter is available in the Setup Wizard.

Stabi Correction

Enable this parameter if Rescue, Stabilisation or GeoLink features are not precise with default settings.

Enable only if model is in a good condition. Suitable for pilots that are flying a complicated maneuvers.

This mode will give off the best performance in any possible maneuver. The only requirement is the model is not generating vibrations that are interfering with the motion sensor. If you are unsure, please use Vibration Analysis and consult with us.

5.8.2 TELEMETRY SETTINGS

ESC Telemetry is feature that enables transmission of the telemetry variables from the ESC to your radio. Covered in the ESC Telemetry page.

5.9 BACKUP TAB

Here, you can save the settings to your Spirit unit before powering off, you can also save the settings to your computer here, Should you need to reload them at a later date.

Profile

This section allows you to Save and Load complete settings of the unit to a specified file. If you have more than one of the same model, it is not necessary to carry out a complete setup again, just load the stored settings easily with the Load button.

Unit

Any changes to the configuration can be saved at any time to the internal flash memory of the unit.

To put all settings to a factory defaults, click Factory Settings.

Remember to save the settings each time you want to store the settings permanently. You must press the Save button. Otherwise, the changes will be lost after the Spirit FBL unit is turned off.

Bank Switching

In case that the Bank Switching is enabled, you can save the settings from single bank or even all banks. To see the differences between Banks you can use Bank Comparison feature.

5.10 UPDATE TAB

If you want to update the firmware, you can do so in this tab.

Firmware

First select the data file containing the firmware (*.4df) – Select button. Once the file is selected, press the Flash button. The upgrade progress will be displayed here. After completion, a confirmation dialog box should indicate a successful update.

Then, unplug the unit from its power source.

Upon the next start it will load with the newly flashed firmware.

Configuration of the unit is not changed, so you do not need to save/load it.

You can get firmware from: spirit-system.com.

6 BANK SWITCHING

This functionality allows you to switch between saved settings during a flight. Switching is done through the transmitter, so that channel's value is changed. This mean that a Bank can store one unique settings. The unit is able to store 3 different banks.

With a transmitter you are able to use a three position switch to switch freely between banks.

Bank switching is disabled by default, so you can decide whether it is useful in your application. You have to activate it by the assignment of Bank function in the General/Channels window. Generally, it is assigned to channel 7.

- Bank 0 – active in range of lower third (impulse under 1400μs).

- Bank 1 – active in range of mid third (impulse between 1400μs to 1640μs).

- Bank 2 – active in range of upper third (impulse above 1640μs).

Initial settings for Bank 1 and Bank 2 are equal to Bank 0. Bank 0 allow you to configure all parameters, while Bank 1, 2 does not allow to set main parameters. For safety, Bank 1 and 2 does not allow you to set any main parameters.

The Bank switching is great for switching between flight styles, sensor gains for low or high RPMs, for slow acro or 3D. Alternatively it can be used just for tuning your settings.

If the software (or a transmitter integration) is connected with the unit then bank switching by assigned switch of the transmitter is temporarily disabled. Then, Bank switching is performed using the software in bottom part of the window. When a bank is switched using the software it is necessary to save your settings to the unit before you switch Banks, or your settings will be returned to the previous (unchanged) state.

Always close the software or any connected app before flying. Otherwise it will be not possible to change Banks by assigned switch of your transmitter.

To verify that the Bank switching is working properly, please start the software and look at the Diagnostic tab. There you can see Bank indicator with the channel bar. Try to change position of assigned switch. If everything is correct, you will see that the Bank number will change there.

7 GOVERNOR

Governor is feature that helps to maintain constant RPM of the rotor head. You can use this feature instead of internal governor from your ESC or other governor. It is designed to work with electric, nitro and gasser helicopters. As result flight performance can be even better.

To achieve proper function it is very important to perform correct configuration. First from all make sure that internal governor is disabled in the ESC.

It is necessary to disassemble rotor blades from your model prior to the governor setup. Do not make any adjustments with motor turned on.

It is required to use Throttle output from the unit when using Spirit Governor.

Full Governor Setup guide is available at the Governor page.

8 SOFTWARE KEYBOARD CONTROL

For fast and easy configuration we have implemented keyboard controls in the software.

| Shortcut | Function |

| F1 to F10 | Switch between tabs. |

| ESC | Exit current window. |

| CTRL + S | Save settings to the unit. |

| CTRL + P | Save profile to your computer. |

| CTRL + L | Load profile from your computer to the unit. |

| CTRL + W | Connection settings for the Wifi-Link module. |

| Numpad 0, 1, 2 | Switch between banks. |

| Tab | Switch between parameters. |

| Space | Select parameter / option |

| Arrows | Increase / Decrease value. |

| Page Up / Page Down | Increase / Decrease value by tens. |

| Home | Set the lowest value. |

| End | Set the highest value. |