Difference between revisions of "Configuration/en"

(Importing a new version from external source) |

(Importing a new version from external source) |

||

| Line 48: | Line 48: | ||

== CONNECTION WITH THE UNIT == | == CONNECTION WITH THE UNIT == | ||

| − | + | If you have already attached the USB interface to your computer, next | |

| + | connect the interface cable to the '''SYS''' port of the Spirit FBL unit. | ||

| + | The Spirit FBL unit can not be powered from the USB cable/SYS port so it is | ||

| + | necessary to power it from either the receiver, a BEC or an external battery | ||

| + | pack. | ||

| + | The RUD and AUX ports are used to power the Spirit FBL unit and if using a BEC | ||

| + | or battery pack it is suggested to connect to these ports with a voltage | ||

| + | between 3V and 15V. | ||

| + | The middle wire must be the positive voltage connection. | ||

'''Never plug a connector for powering the unit to SYS or ELE/PIT/AIL ports.''' | '''Never plug a connector for powering the unit to SYS or ELE/PIT/AIL ports.''' | ||

Revision as of 10:16, 16 September 2016

Configuration is the next and one of the most important steps for correct operation of the system.Configuration is performed using the software, which combines efficiency and simplicity while offering adjustable parameters, including advanced parameters.

The software offers the Setup Wizard. It is highly recommended to use the wizard as it will guide you through entire configuration from the beginning to the first flight.

Contents

1 CONNECTION TO PC

Before you begin the actual configuration it is necessary to connect the system to a computer via a USB port. Depending on the operating system and computer, a driver may need to be installed after connecting the cable to the USB port.

The Spirit Settings is available for the following operating systems:

- Microsoft Windows

- Apple OS X

- GNU/Linux

- FreeBSD

Once connected and the driver is installed successfully a new virtual COM port should be visible in the software and device manager.

MICROSOFT WINDOWS

Install the driver via the software installer. This process will be described in a

following section.

APPLE MAC OS X

For proper functionality it is important to download and install the driver from

the following URL:

http://spirit-system.com/dl/driver/SiLabsUSBDriverDisk.dmg

GNU/LINUX a FreeBSD

Nothing needs to be installed.

1.1 WIFI-LINK

The Spirit Settings software can be connected with Wifi module from now. It is called Spirit Wifi-Link. Wifi-Link can completely replace the USB interface. Thus user can perform all the settings wirelessly. You can find description of the connection with all instructions in the Wifi-Link guide.

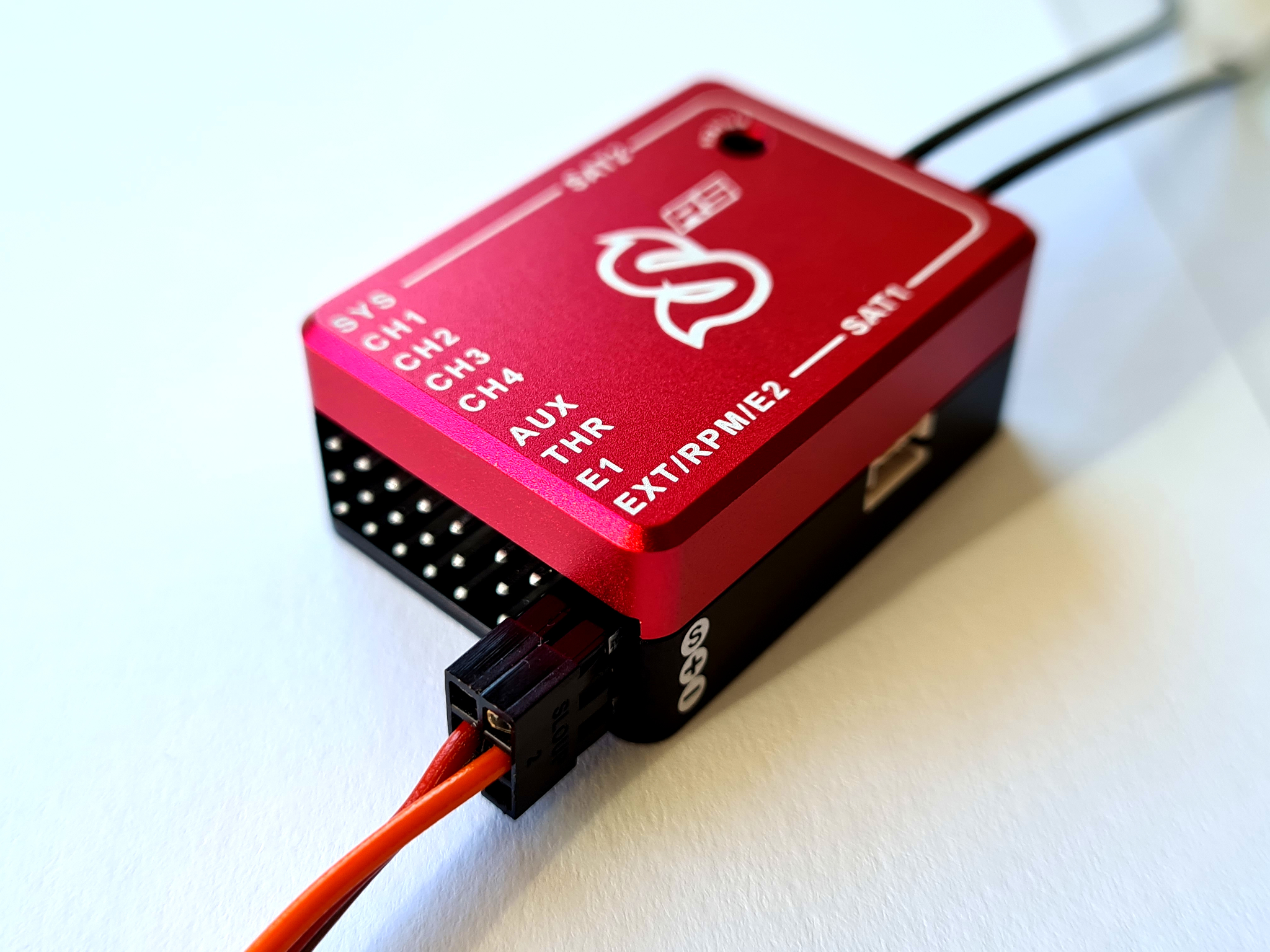

2 CONNECTION WITH THE UNIT

If you have already attached the USB interface to your computer, next connect the interface cable to the SYS port of the Spirit FBL unit. The Spirit FBL unit can not be powered from the USB cable/SYS port so it is necessary to power it from either the receiver, a BEC or an external battery pack. The RUD and AUX ports are used to power the Spirit FBL unit and if using a BEC or battery pack it is suggested to connect to these ports with a voltage between 3V and 15V. The middle wire must be the positive voltage connection.

Never plug a connector for powering the unit to SYS or ELE/PIT/AIL ports.

NOTE

If the unit is not configured yet (e.g. a new unit) it is advised to not connect

any servos yet.

3 INSTALACE KONFIGURAČNÍHO SOFTWARE

Stáhněte software a postupujte následovně v závislosti na operačním systému, který používáte. Je volně dostupný na webu Spirit System - spirit-system.com/.

MICROSOFT WINDOWS

Spusťte stažený software - instalátor a postupujte instalací. Pokud ještě nebyl ovladač nainstalován, zvolte ho v instalátoru k instalaci. Instalátor vás provede až do stavu, kdy je vše v počítači připraveno pro první spuštění konfiguračního software. Spustitelný soubor konfiguračního software se bude nacházet v seznamu programů či na ploše jako „Spirit Settings“.

APPLE MAC OS X

Nainstalujte software poklepáním na stažený soubor DMG. Přesuňte jeho obsah do adresáře Aplikace. Konfigurační software lze poté spustit z Aplikace poklepáním na „Spirit-Settings“.

GNU/LINUX a FreeBSD

Extract all the files from the downloaded archive to, for example, your home

directory.

Configuration software can be launched from the newly created directory

with the file „settings.sh“.

4 CONFIGURATION SOFTWARE

Once the software is installed, ensure your Spirit unit is connected via USB to the SYS port, powered on and initialized (LED lights are on), then run the software on your computer.

Spusťte aplikaci Spirit Settings např. z plochy nebo adresáře, kde byla provedena instalace.

NOTE

The configuration software should be started after the unit has initialized.

Whenever the Spirit FBL is initialized (status LED is on) and connected, you can

make adjustments to the settings.

Configuration during flight is not possible due to the associated safety risks.

PROBLEMS WITH WINDOWS

Pokud konfigurační software nedetekuje COM port k interface, spusťte jej jako Správce – pravé tlačítko myši na settings.exe. V některých případech se po instalaci ovladače přiřadí k interface (zařízení Silabs) vysoké číslo COM portu. Z tohoto důvodu je nutné ve správci zařízení tomuto portu přiřadit číslo menší (např. COM1 – COM4). Na přenosných počítačích je také vhodné vypnout uspávání USB zařízení.

5 SOFTWARE USAGE

After successful connection of the Spirit FBL unit, all configuration features should be accessible. If not, try to either choose another COM port (Device) or try to restart the software, disconnecting the unit from the power supply and repeating the procedure.

Make sure the software is launched after the unit has initialized.

5.1 CONNECTION TAB

Tato záložka indikuje současný stav spojení, informuje o aktuální verzi firmware, zobrazuje sériové číslo jednotky a nebo umožňuje změnu komunikačního zařízení. Mimo to nabízí průvodce provotním nastavením.

We recommend using this wizard, as it will guide you through a basic setup in the easiest and simplest way.

5.2 ZÁLOŽKA OBECNÉ

If you have already set up the unit using the wizard, you can make additional adjustments to your setup here. All values relate to the settings you selected in the wizard.

UPOZORNĚNÍ

Whenever parameters are changed, the new value is immediately applied but

not saved. Unless settings are manually saved, after disconnecting the power

supply all unsaved changes will be lost. (see Backup tab.)

Pozice

Zvolte pozici v jaké je jednotka připevněna k modelu, viz kapitola 3. Montáž.

Swashplate

Select the swash type of your model.

In most cases it is CCPM 120° or CCPM 120° (reversed).

Any swash mixing in the transmitter must be turned off. It must be set to H1 (single servo) type.

Přijímač

Select the type of receiver you are using:

PWM – standard receiver.

PPM – signály přes jeden propojovací kablík.

Spektrum DSM2/DSMX – DSM2 or DSMX satellite.

Futaba S-BUS – receiver connected via SBUS.

Jeti EX Bus – přijímač připojený přes sběrnici EX Bus (integrace s JETI model).

SRXL/SUMD – receiver connected via SRXL, SUMD, UDI.

Letový projev

Sets how the model will behave in flight.

This parameter is used to control and adapt flight behavior according to the

requirements of the pilot.

Lower values mean that the model will behave in a more consistent, controlled manner and will feel more robotic. Higher values mean a more natural behavior. The response to stick movements will be more flybar-like.

Parametr neovlivňuje jak bude model stabilní. Většina pilotů preferuje výchozí nastavení, tj. hodnota 4.

Channels

Po klepnutí na tlačítko je otevřeno okno, kde je možné přiřadit libovolně kanály přijímače na dané funkce. V závislosti na typu přijímače je možné přiřazovat více či méně kanálů. Pamatujte, že je nežádoucí přiřadit stejný kanál na dvě či více funkcí.

When a channel for Throttle function is assigned, throttle output from the unit

can be obtained from the AUX position.

When a channel for Bank function is assigned, then Bank switching is activated

(See chapter 5.6).

When a channel for Gyro Gain function is unassigned, it is possible to configure

gyro gain directly through this software in Sensor tab. The unassigned channel

could be used in another way, e.g. for Bank switching.

Failsafe

For a PPM, Futaba S-BUS, Spektrum DSM2/X, Jeti EX Bus, SRXL/SUMD receiver types you

can set the Failsafe directly in the unit. Channel values are stored

immediately after clicking the Set failsafe button. In case that the signal is

lost for more than 1 second it will set the values automatically in the flight.

With other receiver types the Failsafe is programmed in the transmitter or receiver.

Realtime tuning

Přiřazením parametru (P) je možné provádět nastavení přímo pomocí vysílače. Zvolený parametr je možné pohodlně nastavit na základě výchylky kanálu pomocí řídícího prvku (např. potenciometrem). Pro konfiguraci tedy není nutné spojení s konfiguračním programem, ale postačí běžný vysílač. Změna výchylky kanálu ihned mění hodnotu parametru. Maximální výchylka zvoleného kanálu nastaví nejvyšší možnou hodnotu parametru, minimální výchylka pak tu nejnižší hodnotu. Realtime ladění parametrů má nejvyšší prioritu. To znamená, že nebude použita hodnota nastavená v profilu ani v bankách.

Tato funkcionalita je aktivní pokud není spuštěn konfigurační program, aby se zabránilo případné kolizi. Jakmile je program odpojen, je hodnota zvoleného parametru nastavena na základě výchylky kanálu. Pokud je program znovu spuštěn, zobrazí se hodnota naposledy nastavené výchylkou kanálu. Avšak při spuštěném programu již znovu platí předchozí pravidla (výchylka kanálu nebude mít vliv).

Je možné nastavovat simultánně až 3 různé parametry či funkce.

Pokud je nastavena funkce (F), je aktivní, když je hodnota rovna 1. Funkce Analýza vibrací umožňuje měření vibrací během letu. Tato funkce je dále popsána v kapitole Diagnostika.

When parameter tuning is complete, it is recommended to open the software and save the settings to the unit. Then unassign the parameter so the value can't be changed anymore.

UPOZORNĚNÍ

Ladění doporučujeme provádět vždy s největší opatrností, aby nedošlo ke ztrátě kontroly nad modelem!

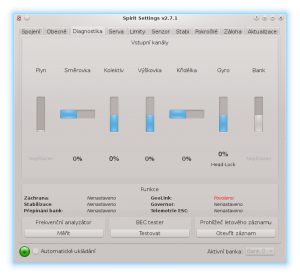

5.3 ZÁLOŽKA DIAGNOSTIKA

Once the settings in the previous tab have been completed, it is now recommended to make any adjustments and changes required in the transmitter so that the transmitter controls match the displayed system's outputs. Generally, each transmitter is different and the center of the channel is never exactly the same. Wear and environmental influences can also have an effect causing the center of the channels to fluctuate. Another consideration is the maximum and minimum value of each channel. Here, you adjust your throws using your transmitter's servo endpoint adjustments.

UPOZORNĚNÍ

For proper operation of the unit, it is necessary that movement of each

channel correspond with the bars. Direction of the movement must be same

as well.

Je nutné také prověřit procentuální hodnotu pro kanál křidélek, výškovky kolektivu a směrovky. Tyto kanály musí být v neutrální poloze kniplů přibližně v 0%! Jednotka automaticky detekuje neutrální pozici při každém spuštění. Do not use subtrim or trim functions on your transmitter for these channels, as the Spirit FBL unit will consider these as an input command.

Ensure all subtrims and trims are zeroed. It is also recommended to set the maximum and minimum values.

Otestujte pákami výchylku kanálů. Pokud jejich hodnoty nejsou přibližně v diagnostice 100%, resp. 100%, je potřeba tento rozdíl (pokud je to možné) dorovnat pomocí funkce vysílače zvané dual rate nebo také travel adjust a to pro oba směry.

After these adjustments, everything should be configured with regards to the transmitter. If some channels oscillate around the center, it may mean wear of the transmitter potentiometers. This can be compensated for by increasing stick deadband in the Advanced tab. (Covered later)

Pokud se zobrazují u kanálu křidélek, výškovky či směrovky hodnoty tučně, znamená to pro jednotku povel k pohybu/rotaci v dané ose.

Kanál gyra zde zobrazuje hodnotu zisku pro vrtulku, kde zisk je ovládán z vysílače. Program dále zobrazuje aktuální režim gyra:

- N – Normal (Rate)

- HL – Head Lock

- HF – Head Lock s aktivní funkcí cykliky, viz parametr Funkce.

FREKVENČNÍ ANALYZÁTOR

Frekvenční analyzátor je nástroj pro měření vibrací modelu. Účelem je diagnostikovat stav a následně určit, které rotující části vytvářejí dané vibrace a za pomocí této informace možné problémy odstranit.

Pro snadné diagnostikování stavu je zde panel "Vibrace", určující celkovou míru vibrací na právě zvolené ose.

It is possible to measure vibrations in three separate axes:

- X - elevator axis

- Y - osa křidélek

- Z - osa vrtulky

- In-Flight - přehrávač vibrací z letu

The live graph shows frequencies for the currently selected axis. This enables you to see both the frequency and magnitude of the vibration on the selected axis.

Vibrations are transmitted to each axes dependent on several, various factors. Frequencies and magnitude are dependent on the model construction. Generally, the vibrations are the highest on Y axis (aileron) but we recommend you check all axes each time you are doing measurement. However vibrations should not exceed 50% for all axes at any time. In the case vibrations are at 90% or more, the model has an issue that needs to be rectified. Should the magnitude exceed 90% on any of the given axes, it is recommended to fix whatever issue is causing these extreme vibrations before flying the model. Even though Spirit FBL unit is highly resistant to vibrations, these could cause unwanted interactions with the Spirit FBL unit and could also cause mechanical failure of the model. Such high vibrations can cause Loctite to fail and other mechanical parts to break.

Vibration levels:

- Vibrace nejvýše 50% - model vytváří vibrace v normě

- Vibrace mezi 50% až 90% - model vytváří značné vibrace

- Vibrace nad 90% - model vytváří extrémní vibrace

As well as overall vibration levels not exceeding 50%, any specific frequency (peak) should not exceed 50%. Anything above this level should be cause for concern and requires further investigation.

For comparing the graphs, you can use the Freeze button. The current live graph is displayed and the graph captured using the Freeze button is saved and will be displayed as subgraph. This graph can be deleted with the Clear button.

It is possible to save the Spectrum analyser graphs. Using the To image button, the current graph will be saved as an image.

The Spectrum analyser is able to detect the vibration frequencies up to 500Hz (rotating parts at speeds up to 30,000 RPM).

Measurement procedure

- Remove main and tail blades from the model.

- Place the model on a suitable, soft surface (e.g. carpet, grass).

- Set blade pitch at approximately 0° on both main and tail rotors.

- Run the Spectrum analyser (this also freezes all servos).

- Spin up the motor to the usual flight RPM.

- Switch between the X, Y and Z axes, saving an image of each.

- Check vibrations in all axes.

- Stop the motor.

Recognizing vibrations

To recognize which component or part is causing abnormal vibrations it is necessary to determine the speed of the highest peaks. The main rotor will have the lowest speed and the tail rotor speed will be approximately 4.5x higher. Generally, the smaller the size of the model, the higher the headspeed will be.

In order to find out which part of the model is causing the unwanted vibrations, move cursor to the peak and check the head speed (RPM). The speed of the main rotor is usually in the range of 1500 to 3500 RPM. Therefore, if the speed is within this range, it is likely that there is a problem with the main gear, main shaft, main shaft bearings or rotor head itself.

Most excessive vibrations are usually, although not always, tail related. To check if there are vibrations coming from the tail you should find the frequency peak that is approximately 4.5x higher than the frequency of the main rotor.

Once you identify which part of the helicopter is causing the unwanted vibrations, you can gradually remove components of the suspect assembly, repeating the measurement process until the vibration disappears. Once the vibration levels have dropped to an acceptable level, you have found the suspect component and can replace it.

Measuring with tail blades installed carries some safety concerns and will also show increased levels of vibration.

NOTE

Gasser motors shouldn't be operated without load! Vibration measurement can't be performed without blades.

In-Flight - vibration analysis from flight

This feature allows you to record vibration spectrum from any moment of the flight. By selected channel you can tell the unit when the spectrum should be taken. The spectrum can be later viewer in the Spirit Settings software with the In-Flight option in the Diagnostic/Spectrum analyzer. Saved vibration spectrum will be stored until unit will lost the power. Saved record is rewritten on repeated activation.

For vibration measurement in the flight set the Special function in the General/Channels. Assign function F: Vibration analysis with axis you want to measure. Then select a channel which will be used for activation of the function.

As soon as the value is equal to 1 the vibration spectrum is saved. The record is saved exactly at the moment when function will change it's state from 0 to 1.

During flight it is enough to change state of selected switch of your transmitter (for example 2-state switch). After landing you can connect unit with the software and open the Vibration analyzer (select In-Flight axis to display the spectrum).

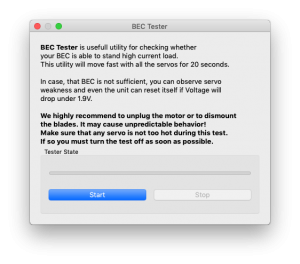

BEC TESTER

The tester is used for determining whether your power supply for the unit, receiver and servos is sufficient. The purpose is to achieve the biggest current spike and verify that your supply voltage will not drop under the safe level.

Click the Start button to start the test. After 20 seconds it should be finished.

If you will observe any issue, then your power supply is insufficient and should not be used. In this case power supply with higher current rating should used.

LOG VIEWER

The log is used to record events during flight. If a problem occurs and the reason isn't immediately known or evident, checking the log can help in identifying the issue.

It works in such a way that it records various events from the time the unit is powered on. If an event occurred you can see this in the log, reporting to the log is done every 10sec. When you click the Open log button you can see the current flight log which contains all the events from the last flight. When the power is disconnected, the log is cleared.

In the case of a major problem occurring during the flight ![]() , the log is then saved permanently to the unit's memory and remains there until such time as the log is opened.

If there is a saved log in memory, the user is advised with the message “Log from previous flight is available!” and the log from the flight when the problem occurred is opened. For example, when a signal is lost or the power supply failed you can find this in the log. The log from the first flight where the major problem occurred is always saved. If this is not opened, then it will not be overwritten with a newer one. In this state, the user is also notified by different cyclic pitch pump during the initialization process - elevator servo will change it's movement direction.

, the log is then saved permanently to the unit's memory and remains there until such time as the log is opened.

If there is a saved log in memory, the user is advised with the message “Log from previous flight is available!” and the log from the flight when the problem occurred is opened. For example, when a signal is lost or the power supply failed you can find this in the log. The log from the first flight where the major problem occurred is always saved. If this is not opened, then it will not be overwritten with a newer one. In this state, the user is also notified by different cyclic pitch pump during the initialization process - elevator servo will change it's movement direction.

The log can contain the following events:

- The model is in good condition. The unit did not recognize any problems.

-

- Sensor calibration was successful.

-

- Governor achieved requested RPM and is active from this moment.

-

- Cyclic achieved its maximum tilt angle. This indicates the model was unable to do the desired correction as necessary. In most cases it is not relevant. But it is possible that the value of the Cyclic Ring parameter is too low and the model can't rotate as fast as intended in the aileron/elevator axes. Alternatively, a too high value for rotational speed could be configured. It is also possible that in fast forward flight the model can pitch-up rapidly. We recommend to set this parameter as high as mechanically possible.

-

- The rudder servo reached its configured limit. When this event occurs before or after a flight it is not a problem. If you see this during flight it indicates that the rudder did not operate correctly. In most cases it is visible during flight as poor rudder response or “blow out”. If the model is set up correctly then it could be due to low rudder efficiency such as the tail blades being too short or headspeed too low. There is also the possibility of a mechanical issue or with the rudder limits being inadequate.

-

![]() RPM Sensor data are too noisy:

RPM Sensor data are too noisy:

- RPM readout is very unstable and are oscilating more than +/- 100 RPM. Data from the sensor are unusable for the Governor. Use additional shielding and mount a ferite rings. Increase value of the RPM Sensor filter parameter in the Expert settings.

-

- Received frame is unusable and will be ignored. In the most cases it does not present any problem. If the event is occuring often, then connection between receiver can be wrong or there is excess noise. Verify quality of the link and check the cable between unit and receiver.

-

- Sensor data reading failed - RPM sensor malfunction probably occured. Sensor is not sending data for 2 seconds or longer. Make sure, that the sensor wiring is correct and that the motor is spinning when Hold is disarmed.

-

- Signal lost suddenly. This problem should not occur at any time and must be resolved before the next flight. There could be a problem with the receiver and/or transmitter antennas. It could be a faulty receiver cable or the connection between the unit and receiver. In some cases signal loss can happen because of electrostatic discharge caused by static build up, this usually occurs in belt driven helicopters.

-

- The main loop was delayed. This can happen when wiring is incorrect or there is abnormal electrical noise interference with the unit, for example, from a BEC. If using the configuration software it could mean the link to the Spirit FBL unit is slower than it should be.

-

- Power supply voltage is lower than 2.9V. This mean you have to use a BEC that is capable of handling higher loads. In rare cases it could be faulty connections in cables.

-

- Vibration level achieved the level that is not normal and can affect integrity of the helicopter. During hard 3D maneuvers the event can occur more frequently.

-

All reviewed logs are saved as PDF files into Documents directory.

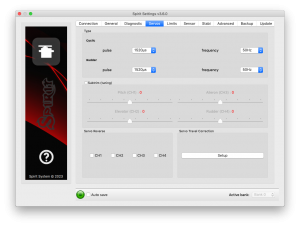

5.4 SERVOS TAB

This tab is used for servo configuration, care should be taken to ensure correct frequencies are used and that the directions are set correctly.

Type

In this section, set the values for neutral pulse and frequency according to your servo manufacturer specifications.

For analog servos the frequency is usually a maximum of 60Hz.

Subtrim (tuning)

Ideally, without the rotor head installed, use a swash leveler to align the swash and servo horns so that the swashplate and servo horns are horizontal and perpendicular to the main shaft.

This is done by ticking the item Subtrim (tuning). This will put the Spirit FBL unit into a special mode where the collective position will be neutral with the servos centered. In addition, stabilization will be disabled.

Servos can easily be adjusted at this time. When completed, the swashplate should be exactly perpendicular to the main shaft and in addition collective pitch should be at 0° (it is possible to measure the pitch angle using a pitch gauge with rotor head and blades attached).

In most cases, it is also necessary for servo horns to be perpendicular to the main shaft. All servos, i.e., CH1, CH2, CH3 and CH4, are set separately on individual sliders. CH1 and CH3 are the aileron servos. CH2 controls the elevator and CH4 controls the rudder.

It is also necessary to set the subtrim and mechanics of the rudder so that the servo horn is perpendicular to its case and rudder pitch is at 0°. This setting will affect rudder stop performance.

Once set up, un-tick the Subtrim (tuning) check box to turn off this special mode.

After exiting the special mode, stabilization and rudder will work again. Be sure your collective pitch channel is configured correctly in the transmitter. That means you should see -100% to 100% in the diagnostic tab. Double check that 0% in diagnostic tab corresponds with middle position of your collective/throttle stick (with linear -100% - 100% collective pitch curve).

Cyclic servos reverse

This allows you to choose which servos should have their direction of motion reversed. While changing the collective pitch all servos should move in same direction. After this settings the model should react correctly to the sticks movement.

This parameter is the most important!

Servo travel correction

Here, you are able to modify and correct travel for each servo individually. Some servos are not very accurate in regards to travel at their limits and this inaccuracy may have a negative impact on flight characteristics. Once in this section of the software, the unit switches to a mode for doing these corrections.

It is expected that in the previous step, Subtrim (tuning), the swashplate was set at zero collective (0° rotor blades pitch). The procedure is such that you should use a swash leveler to determine whether there is any deviation on any of the servos in the lowest and highest points of collective throw. For both positive and negative positions, it is necessary to set the values separately – this is the reason for 6 sliders. If the travel is less than required, increase the value. If too much, decrease. To activate sliders in the secondary part move your collective to opposite direction.

This correction is also useful if there is asymmetric geometry on the helicopter causing issues such as the inability to achieve equal positive and negative pitch values. In this case, it is necessary to modify the positive or negative sliders for all three servos. If you are unsure about your settings, it is better to leave the sliders in the Middle. (position 0)

5.5 LIMITS TAB

This tab affects limits and servo travel ranges.

Cyclic Ring (tuning)

This parameter sets the electronic cyclic ring, which allows the model to achieve the largest cyclic ranges without mechanical binding (binding of servo horns, pushrods and linkages).

This parameter acts as a so-called electronic Cyclic Ring.

The settings here should be done very carefully to avoid damage to the model or it's associated electronics. Otherwise a boomstrike can occur.

First, set your desired collective range, for example, +/-12°. We recommend

using a -100% to 100% linear collective pitch curve in the transmitter.

Now it is time to set the Aileron/Elevator maximum cyclic pitch range.

Try to set the largest possible deflection. This parameter does not directly affect the speed of rotation, but if it is too low, the model may not have consistent pitch and roll rates.

This setting should be done with 0° collective pitch. Then carefully check

maximum stick deflection in all directions to ensure that mechanical binding

does not occur. This should also then be done with maximum and minimum collective pitch. Generally there is no reason to set deflection higher than maximum collective pitch angle. This parameter act as a so called Cyclic Ring.

If you increase the collective pitch range, this parameter must then be checked and in some cases adjusted to insure no binding occurs at your new maximum and minimum pitch ranges. If the selected cyclic ring range is insufficient, it is possible that pitch-up can happen during fast forward flight (even if the pitch-up compensation is at its maximum value). This is because the model will not be able to add sufficient corrections with the configured range.

Rudder end-points (tuning)

Left / Right limit - Sets the minimum and maximum deflection of rudder rotor blades.

We recommend setting these values for both directions to the maximum

allowed range by the manufacturer of the helicopter. Otherwise, the rudder

may not be able to keep the yaw direction during demanding maneuvers and

tail blow outs may occur.

Do not exceed allowed limit for your model.

5.6 SENSOR TAB

This tab is the last important part of the settings which must be configured.

Sensitivity

The rotary dial adjusts the gyro sensitivity for aileron, elevator and rudder axes.

Cyclic gain – The higher the value is, the higher the accuracy within the control loop. The default value is preconfigured to 55% gain, for most models an optimal value of around 60% is suggested.

Rudder Common Gain– 100% means no multiplication. This is the recommended value for 550-class helicopters and smaller. For bigger helicopters it is often higher.130% could be fine. Transmitter gyro gain should be configured to approximately 60% for the first flight.

Rudder Gain – This parameter is enabled only in case of unassigned Gyro gain channel. It replaces function of Gyro gain from the transmitter, so you can directly set the value in the software.

Rudder Gain in the software or in your transmitter can be programmed in this way:

- Head-Lock mode: 1% to 100%

- Normal (Rate) or a special function: -100% to 0%

Negative gyro gain can be used to activate the rescue or the stabilisation modes – check the Stabi tab.

Rotation speed

The default value is 8 and will favor beginners more, the higher the value, the faster the rate of rotation. This factor also depends on the mechanical linkage ratio or D/R (Dual Rate) in the transmitter and also on the Aileron/Elevator limit.

Make sure the value is not too high else it can cause unwanted and inprecise movements.

default value - 8

We recommend to set the Cyclic rotation rate within a range of 8 - 11. Remember that DFC rotor heads tend to rotate faster so it's better to initially start with a lower value for them.

For the Rudder rotation rate pilots are preferring a range of 9 – 11.

5.7 STABI TAB

The Spirit unit offers you the options of model stabilization and rescue mode.The stabilization function, once activated, will recover the model to a horizontal position without any other input from the pilot, this can be used as a “bail-out” feature when trying new maneuvers and can help with the learning process.

Rescue mode complements the normal operation of the Spirit unit. If activated, the model will recover to a horizontal position and add collective pitch as per the settings. This function can be used any time when the pilot loses orientation or control of the model.

The Spirit unit allows you to assign a stabilization or rescue mode using the gyro gain channel. 0 - 100% gain in the transmitter is always heading lock gyro mode and with -100 – 0% gain, you are able to activate stabilization or rescue mode. This means that instead of normal (rate) mode, it will stay in heading hold gyro mode, plus rescue/stabilization is activated. So, while rescue/stabilization mode is activated, a gyro gain of -70% is considered as 70%. This behavior can be also observed in the Diagnostic tab.

Some transmitters have a gyro range of 0 to 100% where 50% is the middle - zero gain (e.g. Spektrum DX6i). Others use a range of -100% and 100%, where 0% is the middle.

Function

Here is where you select which mode should be activated at negative gyro gains.

Disabled - Normal (Rate) gyro mode.

Rescue (Normal) - Recovers the model to an upright horizontal position – skids always to the ground. This recovery mode is great for the beginners.

Rescue (Acro) - Recovers the model to a horizontal position, inverted or upright, whichever is closer at the time of activation. For intermediatte and advanced pilots that are flying acrobatic manouvers.

Stabilization (Normal) – stabilization mode - skids always to the ground. This mode is good for learning the basics such as hovering and slow transitions. Model is always pushed to the horizontal position.

Stabilization (Acro) – stabilization mode - inverted or upright, whichever is closer at the time of activation. This mode is used for learning the basics of acrobatic maneuvers. If the sticks are in the center, the model has tendency for returning to the horizontal position.

Stabilization (Scale) – stabilization mode - skids always to the ground. This mode is used for a scale flying. Gyro mode is Normal (Rate).

Coaxial – stabilization mode - inverted or upright, whichever is closer at the time of activation. The steering behavior is very similar to a coaxial helicopters. Great for learning a hovering practices.

If using these modes, be sure your helicopter is initialized on a flat surface, not tilted to any side. Do not tilt the helicopter for more than 5 seconds.

The rescue mode is very demanding on the BEC. Be sure your BEC can handle such peak loads. In case it is is not sufficient your model could crash! Never exceed angles recommended by manufacturer of the model, else the mechanics can be damaged during the flight!

Flybar mechanic

If your helicopter is equipped with traditional flybar mechanics, you have to enable this parameter in order to use the stabilization or rescue modes. All settings are the same for flybarred helicopters except this parameter.

Flybarless helicopters must be configured and operated with the Flybar mechanic parameter disabled!

Rescue collective pitch

This determines how quickly the model will recover to a horizontal position.

100% means the maximum deflection of the blades, which was configured in the Servos tab.

It is very important to check whether the rescue mode works correctly before the first flight (on the bench without the motor/rotors running).

Collective pitch should be always positive with the rescue engaged - while helicopter is on the ground

Sticks priority

Specifies the amount of control while configured mode is activated.

The higher the value, the more the model will react to stick movements.

Direction control rate

This specifies the rate of controlling direction for the stabilization mode.

Low values are well suited for beginners to get coaxial like behavior. Higher values are more appropriate for scale flying.

Acro Delay

Specifies a time period for the Rescue (Normal), when the model is recovered from the inverted flight. Until the period is reached, the rescue has the same behavior as the Rescue (Acro). In this way, faster ascending to a safe level can be achieved.

5.8 ADVANCED TAB

This tab is for more advanced configuration of the Spirit FBL unit. It is recommended that you fully understand these parameters before adjusting them. However, it is essential to set geometry. Other parameters, however, depend on the preferences of the pilot.

Geometry 6° (tuning)

For proper operation of the Spirit unit, it is necessary to set this parameter correctly. Here, the unit is switched to a special mode for settings 6° of cyclic pitch on the main blades. It is necessary to set the value so that the blades angle is at 6° in the aileron axis. You need to rotate your rotor head with blades to be parallel to the longitudinal axis of the model. A higher value increases the angle; a lower one decreases the angle. Optimal head geometry should be in the range of about 90 – 160. If not in this range, it is recommended to adjust the distance of a ball link on the servo horns or perform other mechanical adjustments.

Collective Direction

Parameter to determine direction of the collective pitch.

In case of a Trailing Edge rotor head or if a mixing arms are present on the rotor head, tick the Reversed option. In the most cases the parameter is unticked.

Correct configuration is very important, else the collective pitch will be reversed.

Elevator filter

This parameter compensates elevator bouncing during aggressive maneuvers. The larger the value, more compensation is involved.

If this value is too high it can lead to a soft feeling in the elevator. We recommend using the default value of 1 to begin with.

Cyclic feed forward

This parameter is used to set amount of direct feel between your sticks and

your model helicopter. The higher the value, the more aggressive the model

will feel and the faster the model will react to stick movements.

If the value is very high, elevator bounce-back effect can occur.

During a tic-toc maneuver you can also observe higher motor load or aileron oscillations, because the model is unable to react fast enough.

Setting this value too high can result in elevator bounce.

If the model feels disconnected and there is a lag between stick inputs and

the model, try increasing this value.

Rudder delay

This is a parameter to smooth rudder movements. It also helps to stabilize the rudder – it is a kind of electronic damping. The faster the servo is, the lower the tail delay should be. For analog servos it is recommended to set this value to around 20-25. For usual digital servos it is mostly between 10 – 15. For very fast servos (~0.04s/60°) the value is 5. In case of a brushless servos it is recommended to set a value of 0 - 2.

If the value is too high, the rudder could start to oscillate or wag or could cause a slow rudder stop.

Rudder dynamic

If the rudder does not stop correctly, for example it overshoots, this behavior can be changed with this parameter.

6 – is the default value.

The larger the value, the more aggressive the behavior of the tail. If the tail overshoots in stops, the value is too high. This parameter also affects the response speed of the stick movement; a higher value means a faster response. If you cannot reach a symmetric stop on both sides you will need to make sure that the tail is centered at 0°. Alternatively, you can lower the rudder limit for that side.

Rudder – Revomix

Revomix (tail pre-compensation) adds rudder in response to collective pitch changes, when the tail needs increased holding. Revomix is independent of the transmitter. By default it is turned off, the user must set the amount required of the pre-compensation.

Allowed values are 0 to 10 with 0 being disabled; in most cases it is not necessary to use this parameter, however, when using low headspeed or on helicopters with a poor performing tail, this setting can be used.

Pirouette consistency

This parameter determines the consistency of pirouettes and holding performance. If pirouettes are not consistent during certain maneuvers, increase the value of this parameter.

This value is individual for every model, it depends on many factors such as: your rudder mechanics, head speed, etc. Before setting this parameter, it is recommended to first set the gyro gains.

If the value is too high, the tail can oscillate or wag. It can also cause poor stop performance. This value should be between 150 and 180.

For brushless servos it is recommended to increase value by 10-15 points.

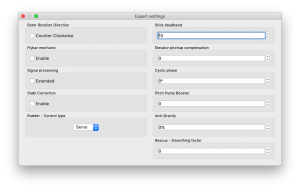

EXPERT SETTINGS

For fine tuning you can set the following parameters. Normally it is not needed to configure any of these parameters.

Rotor Rotation Direction

Parameter to determine rotation direction of the main rotor. In the most cases it is in the clock wise direction - parameter is unticked.

Stick deadband

Determines the area, around center stick, where the system does not recognize any stick movement. If channel readings are inprecise the value should be increased. This can be verified in the Diagnostics tab. This parameter does not replace the Exponential function.

Elevator pitchup compensation

If, during fast forward flight, the model reacts to inputs too rapidly or if the model pitches up, increase this value until this no longer occurs. If the helicopter pitches up abruptly, this could be caused by a cyclic range that is too low and/or too much collective pitch. In this case, you will have to increase the Aileron/Elevator range as high as the model can handle without any binding. If this doesn't fix the problem, you can add more pitch-up compensation.

Cyclic phase

The value indicates the angle by which the swashplate is virtually rotated.

For example a value of 90 will rotate the elevator to aileron. This feature is recommended for models with multi-blade rotor heads. For most other models, we recommend a zero value.

Pitch Pump Booster

To achieve flybar-like collective pitch behavior, you can increase the value until desired feeling is achieved. Remember that higher values are too demanding for power supply and servos on the model.

Signal processing

This parameter is used for operation on models with extreme vibrations that can't be eliminated in any way. This should be enabled only in cases when is absolutely necessary, because flight performance could be affected. It should increase precision of flight and also the precision of rescue and stabilization modes.

RPM Sensor Filter

In case that your RPM sensor has noisy output then RPM readout can be very unstable. This can lead to various problems with Governor. There may be a problem with spool up, flight mode switching or head speed jittering. To make RPM readout very precise, you may need to increase the value.

On the other hand, too high value can lead to a delay, that is unwanted for optimal Governor performance. So the value should be as low as possible while RPM readout is still precise. Variation of 1-20 RPM against the Requested RPM is optimal.

5.9 BACKUP TAB

Here, you can save the settings to your Spirit unit before powering off, you can also save the settings to your computer here, Should you need to reload them at a later date.

Profile

This section allows you to Save and Load complete settings of the unit to a specified file. If you have more than one of the same model, it is not necessary to carry out a complete setup again, just load the stored settings easily with the Load button.

Unit

Any changes to the configuration can be saved at any time to the internal flash memory of the unit.

To put all settings to a factory defaults, click Factory Settings.

Remember to save the settings each time you want to store the settings permanently. You must press the Save button. Otherwise, the changes will be lost after the Spirit FBL unit is turned off.

Bank Switching

In case that the Bank Switching is enabled, you can save the settings from single bank or even all banks. To see the differences between Banks you can use Bank Comparison feature.

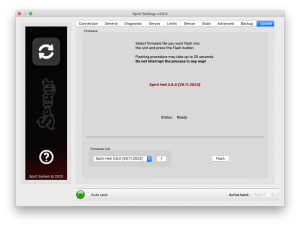

5.10 UPDATE TAB

If you want to update the firmware, you can do so in this tab.

Firmware

First select the data file containing the firmware (*.4df) – Select button.Once the file is selected, press the Flash button. The upgrade progress will be displayed here. After completion, a confirmation dialog box should indicate a successful update.

Then, unplug the unit from its power source.

Upon the next start it will load with the newly flashed firmware.

Configuration of the unit is not changed, so you do not need to save/load it.

You can get firmware from: spirit-system.com.

6 BANK SWITCHING

This functionality allows you to switch between saved settings during a flight. Switching is done through the transmitter, so that channel's value is changed. This mean that a Bank can store one unique settings. The unit is able to store 3 different banks.

With a transmitter you are able to use a three position switch to switch freely between banks.

Bank switching is disabled by default, so you can decide whether it is useful in your application. You have to activate it by the assignment of Bank function in the General/Channels window. Generally, it is assigned to channel 7.

Bank 0 – active in range of lower third (impulse under 1400μs)..

Bank 1 – active in range of mid third (impulse between 1400μs to 1640μs)..

Bank 2 – active in range of upper third (impulse above 1640μs)..

Initial settings for Bank 1 and Bank 2 are equal to Bank 0. Bank 0 allow you to configure all parameters, while Bank 1, 2 does not allow to set main parameters. For safety, Bank 1 and 2 does not allow you to set any main parameters.

The Bank switching is great for switching between flight styles, sensor gains for low or high RPMs, for slow acro or 3D. Alternatively it can be used just for tuning your settings.

If the software is connected with the unit then bank switching via the transmitter is disabled. Then, Bank switching is performed using the software in bottom part of the window. When a bank is switched using the software it is necessary to save your settings to the unit before you switch Banks, or your settings will be returned to the previous (unchanged) state.

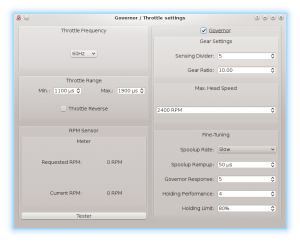

7 GOVERNOR

From firmware version 1.2 governor feature is available! You can use this feature instead of internal governor from your ESC or other governor. It is designed to work with electric, nitro and gasser helicopters. This can make flight performance even better because of constant head speed.

To achieve proper function it is very important to configure your ESC and then the unit. First from all make sure that internal governor is disabled in the ESC.

It is necessary to disassemble rotor blades from your model prior to the governor setup. Do not make any adjustments with motor turned on.

Governor feature can be used with the following receiver types:

Spektrum DSM2/DSMX, Futaba S-BUS, Jeti EX Bus, SRXL/SUMD.

It is necessary to use throttle output from the unit when using governor. Throttle output is at the AUX port. You must connect the ESC or throttle servo there.

7.1 Sensor Wiring

Signal from a RPM sensor should be connected to the PIT pin (middle pin of the ELE/PIT/AIL port).

- ESC with RPM output

- For electric helicopters the best and the easiest solution. You can use RPM output cable that is present on the ESC.

- ESC without RPM output

- In case that your ESC has no RPM output you will need a separate RPM sensor that can be connected to phases of the motor. Important is to power the sensor properly. Voltage can't exceed allowed level for the sensor. Recommended voltage range can be obtained from the sensor manufacturer. In case that the sensor require 3.3V you can connect it to the satellite connector in the unit (Details in the following photo). You can also use the Spektrum adapter.

- In case that the sensor is powered improperly it can be damaged along with the unit.

- Magnetic sensor

- In case that your ESC has no RPM output you will need a separate RPM sensor that can be connected to phases of the motor. Important is to power the sensor properly. Voltage can't exceed allowed level for the sensor. Recommended voltage range can be obtained from the sensor manufacturer. In case that the sensor require 3.3V you can connect it to the satellite connector in the unit (Details in the following photo). You can also use the Spektrum adapter.

- In case that the sensor is powered improperly it can be damaged along with the unit.

Red (+3.3V), Brown (GND).

7.2 Prerequisites

Electric

- Set throttle range in your transmitter so that 0% and 100% throttle position matches with value of the throttle bar in the diagnostics tab. This can be done by Subtrim function in your transmitter and/or Travel Adjustment function.

- Re-calibrate throttle range according to instructions of your ESC. In the most cases it can be configured by powering the model with throttle stick with 100% throttle and then by moving the stick down to 0%.

- If possible, configure fast spoolup mode in the ESC so the governor will be unaffected.

Nitro / Gasser

- Set the throttle range in your transmitter so that 0% and 100% throttle position matches with value of the throttle bar in the diagnostic tab. This can be done by Subtrim function in your transmitter and/or Travel Adjust function.

7.3 Activation

To activate Governor feature in the unit, you will need to assign Throttle function in the General tab/Channels. Then you will be able to enter Governor Settings in the General tab.

7.4 Settings

First from all basic settings are necessary so the governor can control the head speed correctly.

Throttle frequency

To achieve the fastest governor reaction it is necessary to set the highest possible frequency. For ESC it could be only 60Hz, but mostly all can work even with 200Hz. If you are unsure, please contact manufacturer of the ESC. For combustion helicopters it is max. operating frequency of the throttle servo.

Throttle Range

This parameter can affect output from the unit so you can fine-tune ranges precisely. For electric helicopters this parameter is optional. But in case that your ESC does not allow to calibrate throttle range correctly, you can do so here. For Nitro and Gasser helicopters you have to configure it always so the Throttle servo range matches range for the motor.

Throttle Range - Min.

Value of the lowest throttle signal. Default value: 1100 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

You should set the lowest position when the motor is not spinning up anymore – is halted. While configuring this, the motor can start so you have to be very carefull.

Throttle Range – Max.

Value of the highest throttle signal. Default value: 1900 μs. For electric helicopters this value should be specified by manufacturer of the ESC. It is often specified in value of miliseconds (ms).

The value should be configured to match with 100% throttle output programmed in your ESC or full throttle of the motor. If this parameter is not high enough you will be unable to tune Governor because there will be not enough room to compensate high loads. If configured too high then you can observe that after high load head speed will not drop immediately but can be there even for few seconds. When Min. parameter is changed it is also necessary to update this one.

Throttle Reverse

Especially for Nitro and Gasser motors you can set correct compensation direction for the servo here.

Gear Settings - Sensing Divider

Electric motor: Motor poles / 2. For a 10 pole motor set divider to number 5. Mostly configured to 3 – 5.

Nitro/Gasser motor: Number of all active magnets. Mostly it is 1 – 2.

Gear Settings - Gear Ratio

Gear Ratio of the helicopter between the main wheel and pinion of the motor. For example: 120T main gear / 12T pinion = 10.

Max. Head Speed

Configure max. head speed that should be achieved with 100% throttle curve. For example: If you know that you won't exceed 2500 RPM then you can set the value to 2500. With 80% throttle curve your head speed will be 2000 RPM (2500 * 0.80 = 2000).

Fine-Tuning – Spoolup rate

Configure speed of the motor spoolup. For initial tests we recommend Slow spoolup rate.

Fine-Tuning – Spoolup Rampup

Value that will be added at the beginning of motor spoolup – when Hold is turned off. If the spoolup is not smooth, i.e. motor will start with a kick, the value is too high. If the spoolup has a delay, the value is too low. Default value of 50 μs should work fine in the most cases.

Fine-Tuning - Governor Response

This parameter is the most important one to achieve fast and proper response of the governor. It determine how fast the governor should react to a short-term load. Thus optimal settings are required. If configure too low or too high, rudder will not hold properly and can oscillate. Governor can greatly affect rudder performance so you can achieve better holding behavior. Too high value will result in overspeeding during e.g. pitch pump.

Fine-Tuning - Holding Performance

Determine how well the head speed is maintained during a long-term load. If value is too low then during e.g. tic-toc maneuver head speed can drop gradually. In case it is too high then after the tic-toc head speed can be higher than necessary and can even return to requested RPM with noticeable delay. It is better to start governor tuning process with low value.

7.5 Fine-Tuning Procedure

Firstly you have to finish basic setup including Max. Head Speed. Throttle curve in the transmitter must be FLAT. We recommend to set the throttle curve for example to flat 70%, 80% or 90%.

After disarming Throttle Hold you should immediately see Requested RPM in the software – this is desired head speed that should be maintained. Current RPM is head speed that is currently on the rotor head. If Current RPM is not calculated properly, then there is a problem with Gear Settings. In case that you can see zero or random Current RPM value then there is a problem with RPM Sensor and must be fixed.

Performance tuning procedure

We recommend to set the following values for the beginning:

- Governor Response: 5

- Holding Performance: 1

- You should start with increasing the Governor Response. You can do so until RPM is constant enough while doing aggressive collective pitch changes during hovering. When you will notice an overspeeding (RPM is higher than initially was) then the value is too high. In case that the value is too low or too high then the rudder performance can be affected negatively as well.

- When the Governor Response is well tuned, you can continue with increasing the Holding Performance parameter. In case that the value is too low, you will notice poor holding performance during demanding maneuvers with longer duration such as loop or tic-toc. If the value is too high, you can observe that the head speed is unstable even during stationary hovering.

Governor Response: 6 and Holding Performance: 5 may work fine for wide range of the helicopters.

NOTE

- Throttle calibration of the ESC is possible only if the Governor is disabled in the unit.

- For throttle curve under approx. 50% governor is inactive – throttle is controlled directly.

- You should see “Governor was Engaged” event in the log after spoolup with enabled governor.

- Governor Bailout function can be activated whenever the throttle signal is higher than 1250 μs which is approx. 12% throttle curve. If the signal is lower then smooth spoolup sequence is activated.

- In case that the Current RPM value is 4000 RPM measurement is out of range. It may be needed to change count of the active magnets.

- If governor does not react correctly during Throttle Curve changes or even during spoolup, it is most probably result of an excess noise in the RPM sensor or connection. You may consider to use a proper shielding. Increasing value of the RPM Sensor filter in the Expert settings can solve the problem.

- List of the supported RPM sensors and their wiring will be updated on the forum.

8 SOFTWARE KEYBOARD CONTROL

For fast and easy configuration we have implemented keyboard controls in the software.

| Shortcut | Function |

|---|---|

| F1 to F10 | Switch between tabs. |

| ESC | Exit current window. |

| CTRL + S | Save settings to the unit. |

| CTRL + P | Save profile to your computer. |

| CTRL + L | Load profile from your computer to the unit. |

| CTRL + W | Connection settings for the Wifi-Link module. |

| Numpad 0, 1, 2 | Switch between banks. |

| Tab | Switch between parameters. |

| Space | Select parameter / option |

| Arrows | Increase / Decrease value. |

| Page Up / Page Down | Increase / Decrease value by tens. |

| Home | Set the lowest value. |

| End | Set the highest value. |